Reliable Decisions Start with Reliable Equipment Data

Every reliability strategy relies on quality data. Outdated or incomplete records keep teams reactive and behind the curve. The Sensei System ensures accurate, timely collection without clipboards, memory lapses, or chance. By automating monitoring and simplifying manual logging, Sensei bridges the gap between what’s happening in the field and what gets acted on.

- Continuous visibility across all assets

- Centralized logs replace paper silos

- Verified proof of maintenance activity

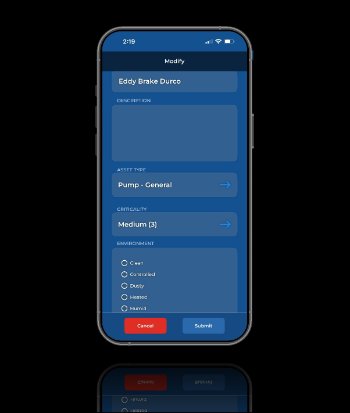

- Context-rich records with every reading

- Early warnings enable proactive action

- Data-driven decisions replace assumptions

Know What's Going On

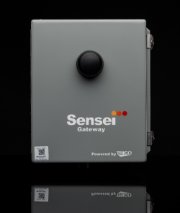

Sensei

Flexible Devices. One Unified Strategy.

Powerful Alone. Stronger Together.

Each Sensei data collection tool can deliver value on its own. But when connected across your facility, they create a complete, always-on condition monitoring system.

- Only need oil level tracking? Start with the Sensei-Enabled Opto-Matic Oiler.

- Focused on vibration and temperature? Deploy Machine Vitals.

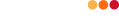

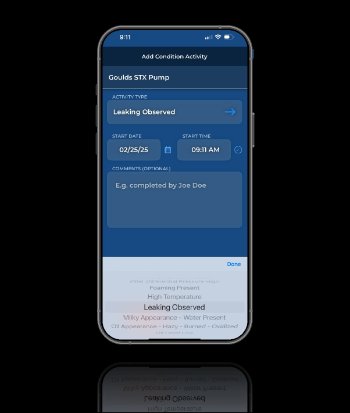

- Want a full history of what’s been done? Use the Mobile App.

- Ready for a fully integrated approach? Combine all for a real-time view of asset health and reliability actions.

Whether you're upgrading one asset or outfitting your entire plant, Sensei Devices fit your current needs and scale with your future goals.

Explore the Sensei System

Sensei isn't just a single tool, it's a complete ecosystem that works together to track, transmit, and interpret your equipment data. From smart devices to an intuitive dashboard, each component plays a part in giving you clear, real-time view of your asset health.