Aaron Hyatt

08.05.2025

How Machine Vitals Flagged a Hidden Humidity Issue Before It Escalated

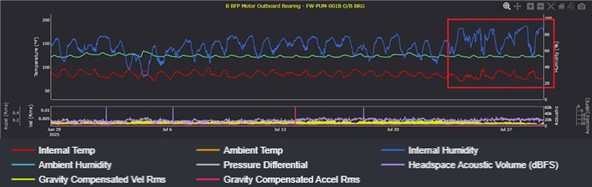

At a major waste-to-energy facility, the Machine Vitals platform recently raised an alert for elevated internal relative humidity in one of the plant’s outboard motor bearings. This wasn't just another environmental anomaly it turned out to be an early warning for a deeper problem.

The Early Warning: One Motor Out of Many

Over the past ten days, the facility had experienced unusually hot and humid weather, typical for late July in the Southern United States, where dew points hovered between 65–75°F and nighttime humidity routinely exceeded 85–95%. Despite these extreme conditions, only one unit triggered an alarm, thanks to its internal humidity readings from Machine Vitals.What made this noteworthy? While all motors were exposed to the same environment, this particular unit’s internal temperature was nearing the dew point during early morning hours, creating ideal conditions for condensation to form. That made it more vulnerable, and Machine Vitals caught it.

Digging Deeper: From Alarm to Root Cause

After reaching out to the customer, a deeper issue came to light: a moisture leak in a nearby system, located just adjacent to the flagged BFP motor checkpoint. The leak had started exactly a week earlier—the same day Machine Vitals data showed a noticeable uptick in humidity inside the bearing housing.

Although the site had already installed a trap breather on the unit (used to mitigate moisture ingress), the internal sensor still showed high humidity. Upon inspection, the breather still had usable life, but ongoing water discharge from the neighboring system was identified as the likely source of the problem. The facility has since diverted the water flow and will prioritize sampling this bearing in its upcoming Q3 oil analysis.

Of particular interest: in 10 years of historical oil data (20–30 samples), this bearing has never recorded a water concentration above 100 ppm. This is uncharted territory—and a great example of Machine Vitals offering insights traditional monitoring never captured.

Turning Data into Action—and Trust

The facility's trust in Machine Vitals and the broader Sensei Enabled Opto-Matic Oiler ecosystem is growing fast. The primary site contact now keeps the dashboard open on one of his three monitors daily. They’ve added additional key personnel, including the site supervisor and operations manager, to the platform. Machine Vitals is no longer just another data tool, it’s become part of their operational rhythm. Especially valued right now: the surface temperature feature and the ability to detect and visualize humidity spikes. Their regional reliability engineer has even incorporated Machine Vitals data into annual planning discussions. Leadership is now advocating for broader deployment of both Sensei Enabled Opto-Matic Oiler and Machine Vitals across all critical sites.

Especially valued right now: the surface temperature feature and the ability to detect and visualize humidity spikes. Their regional reliability engineer has even incorporated Machine Vitals data into annual planning discussions. Leadership is now advocating for broader deployment of both Sensei Enabled Opto-Matic Oiler and Machine Vitals across all critical sites.