See More. Know Sooner.

Multi-Channel Equipment Monitoring for Complete Asset Health

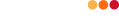

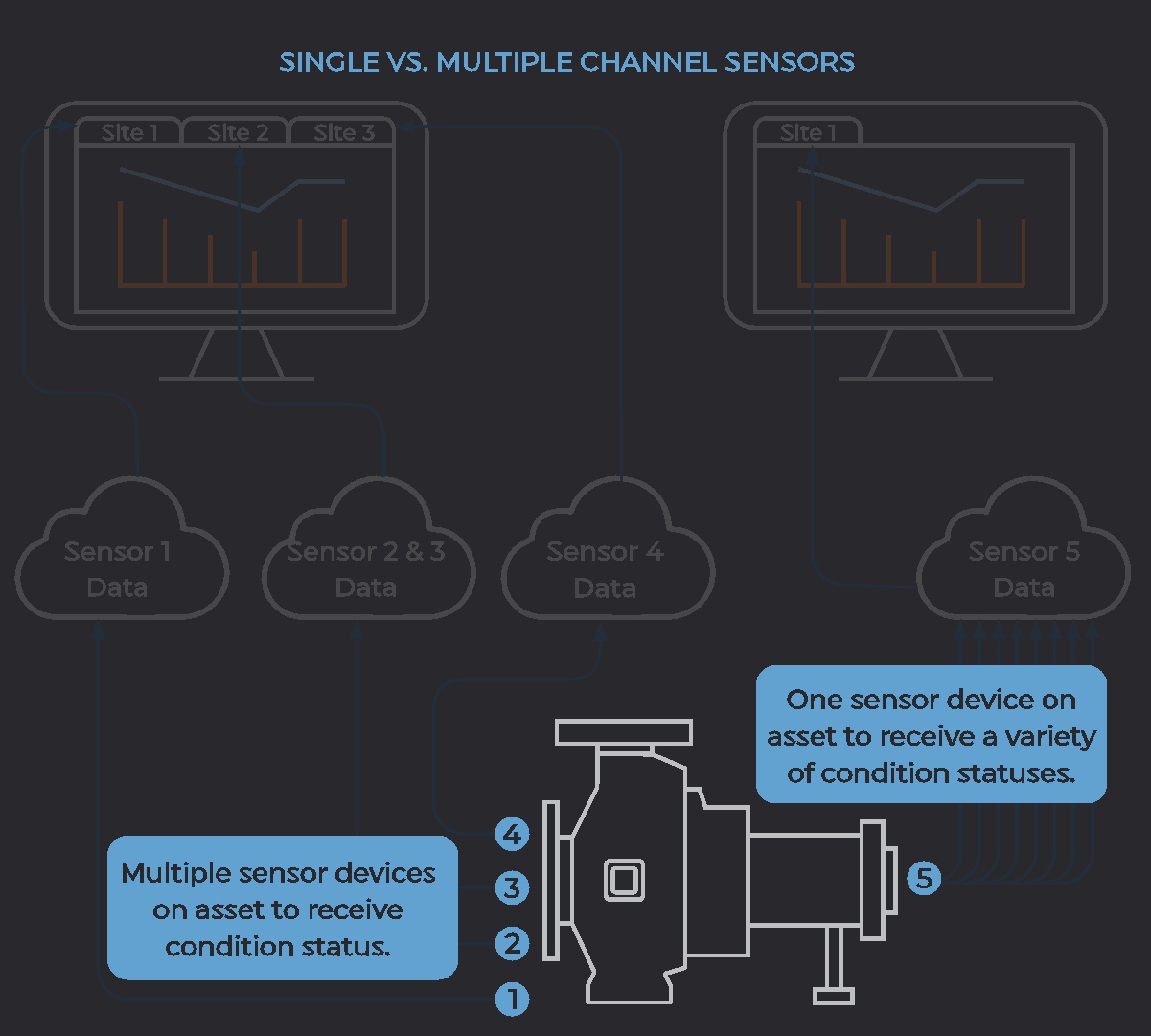

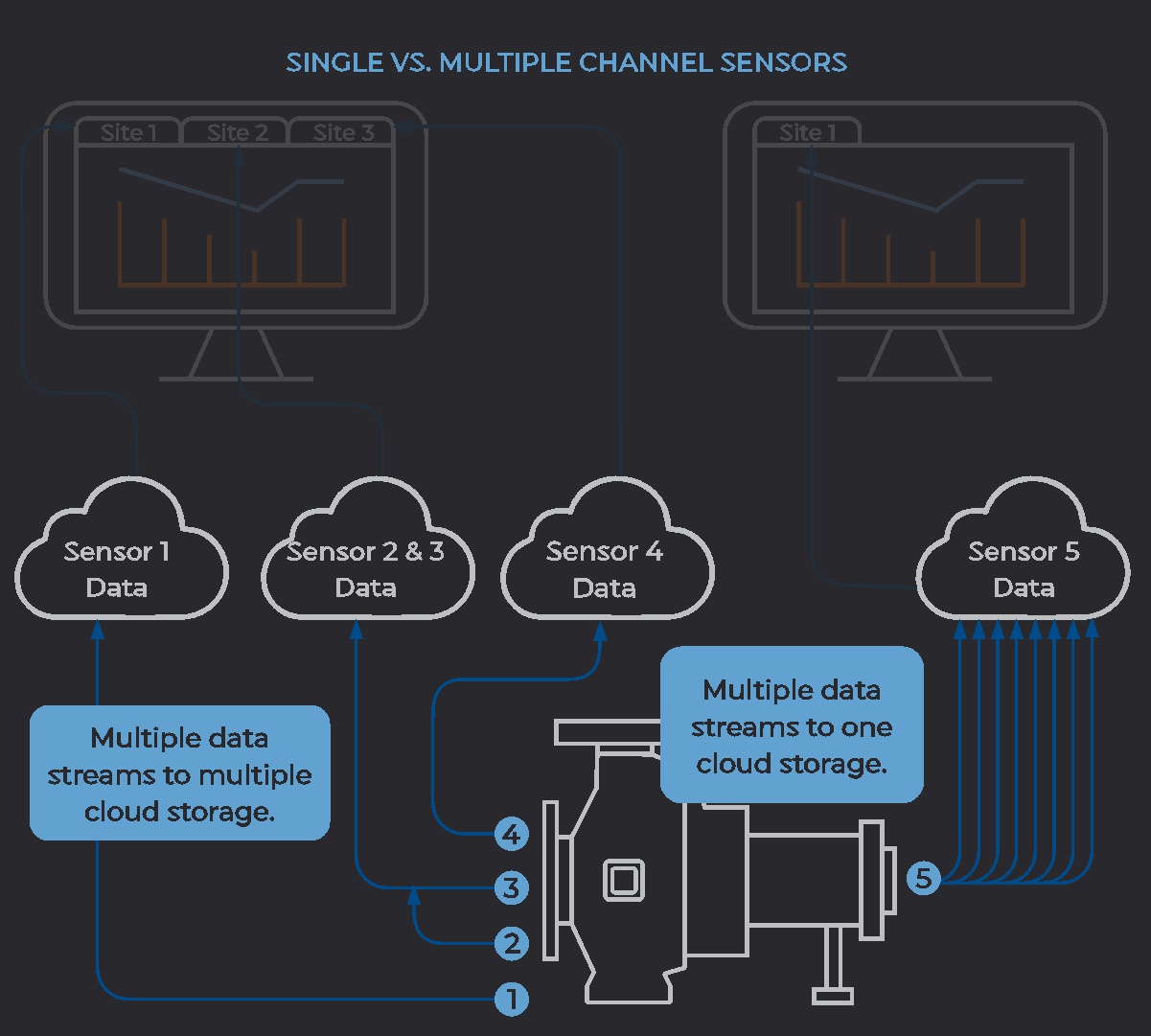

Most sensors focus on a single data point, like vibration or temperature, alerting you only after damage has already begun. The Sensei System changes that. By monitoring multiple channels at once, temperature, vibration, humidity, pressure, oil level, and more. It provides the full picture of asset health.

The result? Earlier insights, clearer trends, and confident maintenance decisions before failures occur.

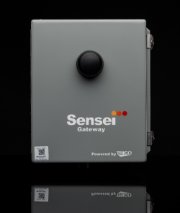

How the Sensei Condition Monitoring System Works

Sensei isn't just a single tool, it's a complete ecosystem that works together to track, transmit, and interpret your equipment data. From smart devices to an intuitive dashboard, each component plays a part in giving you clear, real-time view of your asset health. The system is built on three connected pillars:

Supporting Every Stage of Equipment Health

The Sensei System supports reliability goals at every stage. Here’s how it helps:

Quick & Easy Set Up

Installation & Commission

Sensei Devices are built for easy installation and quick pairing, helping you set up equipment with reliable, accurate monitoring from day one.

Condition Monitoring & Data

Operation & Monitoring

Once installed, the system monitors asset conditions like vibration, oil level, pressure, humidity, and temperature. Data is captured and transmitted securely, giving you a live view of equipment status across the plant without routine walk arounds.

Reduce Unplanned Downtime

Maintenance Planning

Instead of relying on fixed schedules or guesswork, Sensei helps prioritize maintenance based on actual equipment condition. The Sensei Web App reveals which assets are stable, which need attention, and when to take action, helping reduce unplanned downtime and optimize labor hours.

Preventative Maintenance

Failure Prevention

By detecting early warning signs, like rising temperature or changing vibration patterns, the Sensei System helps you intervene before minor issues become major failures. Automated alerts surface issues early, giving your team clarity to respond before small problems escalate.

Better Equipment Performance

Lifecycle Extension

Over time, consistent monitoring and timely maintenance lead to better equipment performance and longer life. The Sensei System helps reduce wear, avoid premature replacements, and keep your critical assets running efficiently year after year.

Machine Health Monitoring for Every Role

Right Data. Right Person. Right Time.

Sensei connects maintenance teams, operators, engineers, and managers giving each role the insights they need:

Maintenance Teams

Keep assets running. Log what matters. Sensei System automates equipment condition checks and makes it easy to log maintenance activities on the go, so nothing gets missed or delayed.

Operations Managers

Know what's running. Know what's not. Gain real-time visibility into equipment status, spot issues early, and avoid unexpected downtime that disrupts production.

Reliability Engineers

Analyze. Improve. Prevent. Use data and historical trends to identify root causes, optimize performance, and drive reliability improvements.

Plant Management

See the big picture. Act with confidence. Sensei System delivers high level insights and alerts to help managers prioritize actions, plan proactively, and justify maintenance strategies.