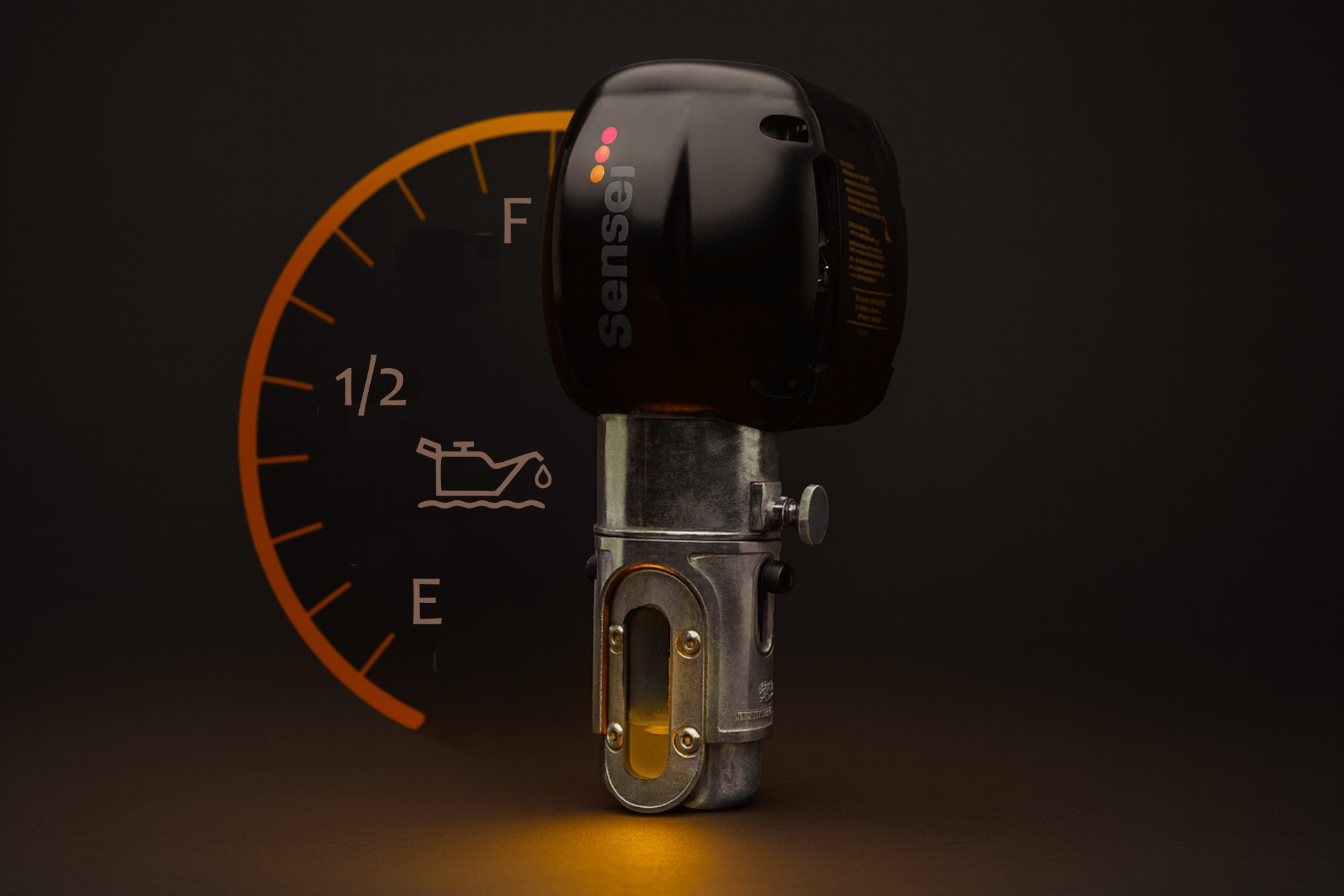

Trusted Oiler. Added Intelligence.

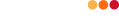

Sensei-Enabled Opto-Matic Oiler: Smart Oil Level Monitoring for Industrial Equipment

The trusted reliability of the Opto-Matic Oiler, now with real-time intelligence. Designed for bearing housings, it maintains precise oil levels while monitoring ambient temperature and lubricant usage trends. This data provides clear insights into asset health and helps prevent lubrication-related issues.

Constant Level Oiler with Integrated Condition Monitoring

The Sensei-Enabled Opto-Matic Oiler goes beyond supplying lubricant, it continuously monitors oil level and ambient temperature around the oiler. These measurements provide early indicators of potential problems.

Tracking ambient temperature conditions identify overheating risks and environmental stresses that can affect performance. Even moderate temperature shifts can accelerate lubricant breakdown, reduced viscosity, or impending component wear.

Continuous oil level monitoring reveals slow leaks, excessive consumption, or restricted oil flow into the housing. Sudden drops could indicate seal failure or internal component issues.

By combining oil level and ambient temperature data, the system highlights trends that would otherwise be missed between manual checks. With Sensei, you’re not only protecting the lubricant; you’re safeguarding the entire asset.

Traditional vs. Smart Oiler: Condition-Based Lubrication Management

When you compare traditional oilers to the Sensei-Enabled Opto-Matic Oiler, the gap is clear. This isn’t just an upgrade, it’s a new way of seeing, predicting, and preventing lubrication-related failures.

Decisions Based on Lack Of Or Incomplete Data

Traditional Oiler

Decisions Based On Continuous Data Feed

Sensei Enabled Oiler

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerTime-based maintenance

Decisions Based On Continuous Data Feed

Sensei Enabled OilerMaintenance done on a fixed schedule, regardless of actual oil condition or usage.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerCondition-based maintenance

Maintenance is triggered only when real data shows it’s needed reducing waste and avoiding premature servicing.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerTechnician "pencil wagging" verification

Decisions Based On Continuous Data Feed

Sensei Enabled OilerOil level and temperature are noted manually, often subject to human error, false checks, or inconsistency.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerAutomatic activity verification

Sensor data creates a reliable digital record.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerLimited historical oil level data

Decisions Based On Continuous Data Feed

Sensei Enabled OilerOnly snapshots from inspections, no visibility on how oil levels change over time.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerContinuous oil level trending

Full history of oil level changes, helping identify slow leaks, consumption rates, and abnormal trends.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerUnknown time without sufficient oil

Decisions Based On Continuous Data Feed

Sensei Enabled OilerNo way to know if the asset ran for minutes or weeks at unsafe oil levels.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerDuration without sufficient oil

Exact total duration is recorded, aiding risk assessment and post-event analysis.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerUnknown consumption rate

Decisions Based On Continuous Data Feed

Sensei Enabled OilerConsumption patterns are invisible without constant monitoring.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerTotal and rate of oil consumption

Tracks exactly how much oil is used and at what pace, enabling more precise planning.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerGuessing which assets need attention

Decisions Based On Continuous Data Feed

Sensei Enabled OilerCrews often spend time checking healthy assets while others go unnoticed.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerConsolidated asset view at a glance

A dashboard ranks oilers by need, focusing labor on priority equipment.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerLimited or no condition-based KPIs

Decisions Based On Continuous Data Feed

Sensei Enabled OilerKPI data is based on inspections, not actual asset condition.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerCondition-based KPIs

KPIs are built from live condition data, improving reliability and reporting accuracy.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerInconsistent inspections

Decisions Based On Continuous Data Feed

Sensei Enabled OilerChecks can be skipped due to equipment location, safety hazards, or time constraints.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerContinuous, effortless monitoring

24/7 monitoring with no gaps, regardless of access or shift timing.

Decisions Based on Lack Of Or Incomplete Data

Traditional OilerNo prediction on refill timing

Decisions Based On Continuous Data Feed

Sensei Enabled OilerMaintenance teams rely on guesswork to decide when to refill oilers.

Decisions Based On Continuous Data Feed

Sensei Enabled OilerPredicts days remaining until oiler refill

Uses current level, consumption trends, and historical patterns to forecast days until oiler is empty.

Where it Delivers the Most Value

It’s not about where you can use it, it’s about where you can’t afford not to.

Climbing ladders, walking long routes, or shutting down equipment just to check oil levels eats up valuable time. Continuous monitoring gives you the data without the trip, so teams can stay focused on what matters most.

For machines where every minute of downtime costs thousands, real-time monitoring provides an early warning system. Even small shifts in oil level or ambient temperature can prevent a failure that would otherwise take production offline.

Not every machine is easy, or safe, to access. In high-heat, chemical, or otherwise risky environments, the oiler provides eyes on lubrication status without putting people in harm’s way.

With smaller crews covering more ground, automation matters. By cutting routine oil checks, the oiler frees up skilled workers to concentrate on assets that truly need attention.

Repeated bearing or seal issues are often symptoms of lubrication problems. The oiler’s continuous data uncovers patterns invisible to manual checks, helping maintenance teams get to the root cause and stop the cycle.

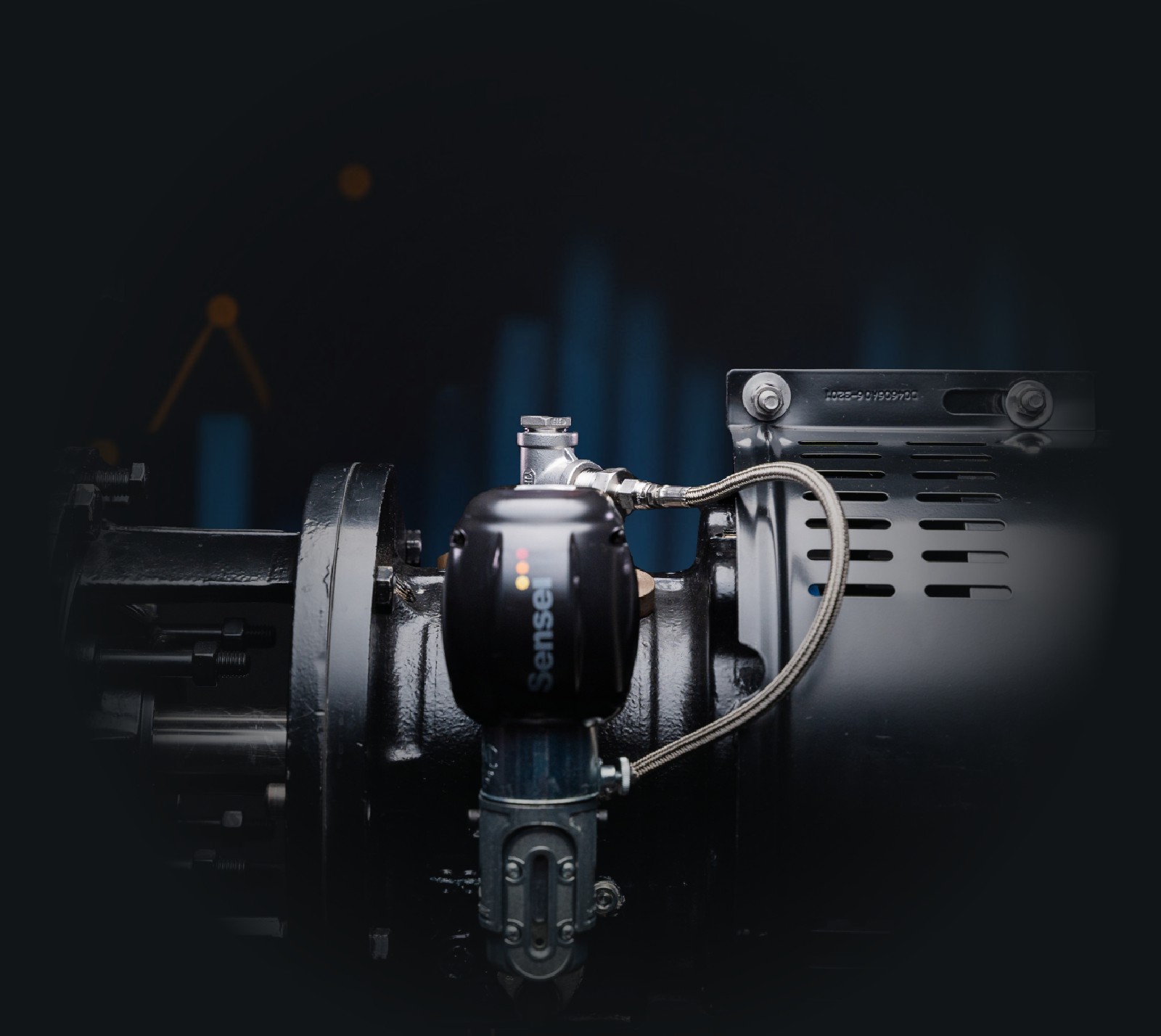

Additional Features

- Lubricant Monitoring

- Continuous monitoring of reservoir oil level and ambient temperature

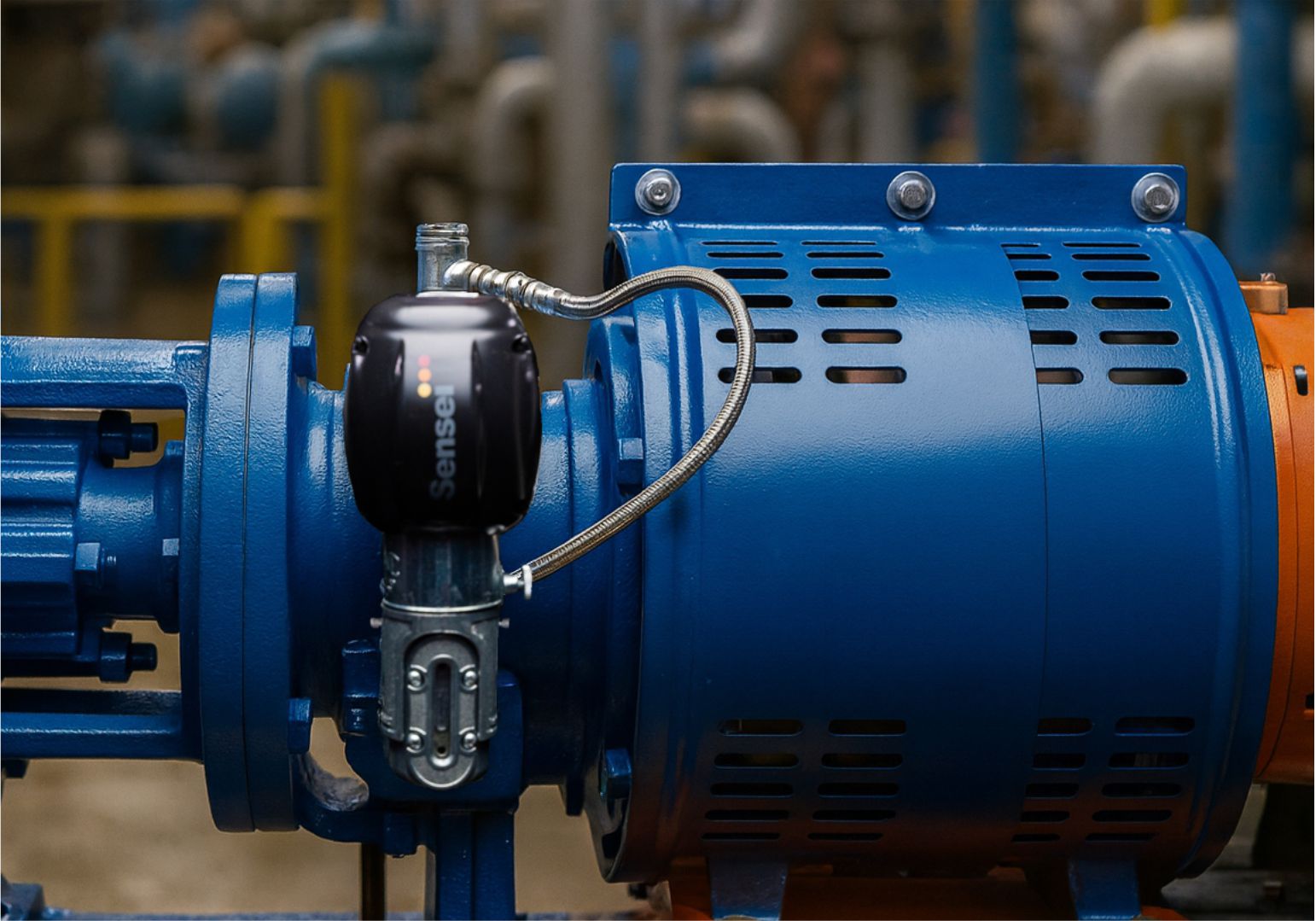

- Simple to Integrate

- Sensing devices install in minutes on your equipment

- Battery Life

- Minimum 3-year battery life. Batteries are replaceable.

- Closed System

- Prevents ingression of contaminants into the lubricant

- Sight Gauge

- Two-inch sight gauge for easy viewing of oil level. Oil level can be viewed through Sensei Platform as well.

- Reservoir

- One piece glass reservoir ensures constant level function.

- Oil Level Range

- Adjustable level setting with 0.68” range.

Other Specs

| Model | Description | Oiler Type | Intrinsically Safe | Kit Option | Capacity |

|---|---|---|---|---|---|

| 38120 | Sensei Enabled Closed System Opto-Matic Oiler, Instrinsically Safe | Closed System | Yes | No | 8 oz |

| 38121 | Sensei Enabled Vented Opto-Matic Oiler, Intrinsically Safe | Vented | Yes | No | 8 oz |

| 38130 | Sensei Enabled Closed System Opto-Matic Oiler, with EX Breather and Braided Line | Closed System | Yes | Yes | 8 oz |

-

Dimensions5” x 3.25” 4”

-

MaterialHousing PC/ABS, Seal: TPE

-

IntegrationSensor Mounted to #5 (8 oz) Opto-Matic Closed System Oiler or Vented Opto-Matic Oiler

-

Oil Level Measurements1/8” Increments

-

Wireless2.4 GHz – Low power network based on 802.15.4

-

Wireless Range100 m Indoor Line of Sight

-

ProtocolsMQTT

-

LEDProvides feedback on connection to network

-

InstallationIndoor or Outdoor (Ingress Protection – IP65)

-

Operating Temperature-4° to 122°F (-20° to 50°C)

-

Wireless SecurityDevice Authentication

AES-128 Encrypted Network Joining Scheme

Pre-Shared Key and Rotating Session Key

AES-128 Encrypted Secured Data Transmission

-

ETL CertificationClass I, Zone 0, AEx ia IIC T4 Ga

Class I, Division I, Groups A, B, C, D T4

Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C -

IECEx CertificationEx ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C

-

ATEX CertificationEx II 1G Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C

-

UKEX CertificationEx II 1G Ex ia IIC T4 Ga | -20°C ≤ Ta ≤ 50°C

Customer Testimonials

Frequently Asked Questions About Sensei-Enabled Opto-Matic Oiler

Explore the System

Sensei isn't just a single tool, it's a complete ecosystem that works together to track, transmit, and interpret your equipment data. From smart devices to an intuitive dashboard, each component plays a part in giving you clear, real-time view of your asset health.