Complete Equipment Data for Accurate Predictive Analytics

Every Sensor Reading. Every Log.

Sensei-Enabled Devices continuously monitor vibration, temperature, humidity, and other critical parameters. Meanwhile, the Trico Companion Mobile App is used to record observations and maintenance activities that sensors can’t detect. Together, these streams create a complete, real-time view of your assets in the Sensei Web App.

Four Dimensions of Equipment Health Analysis

Sensei organizes condition monitoring data into four distinct insights:

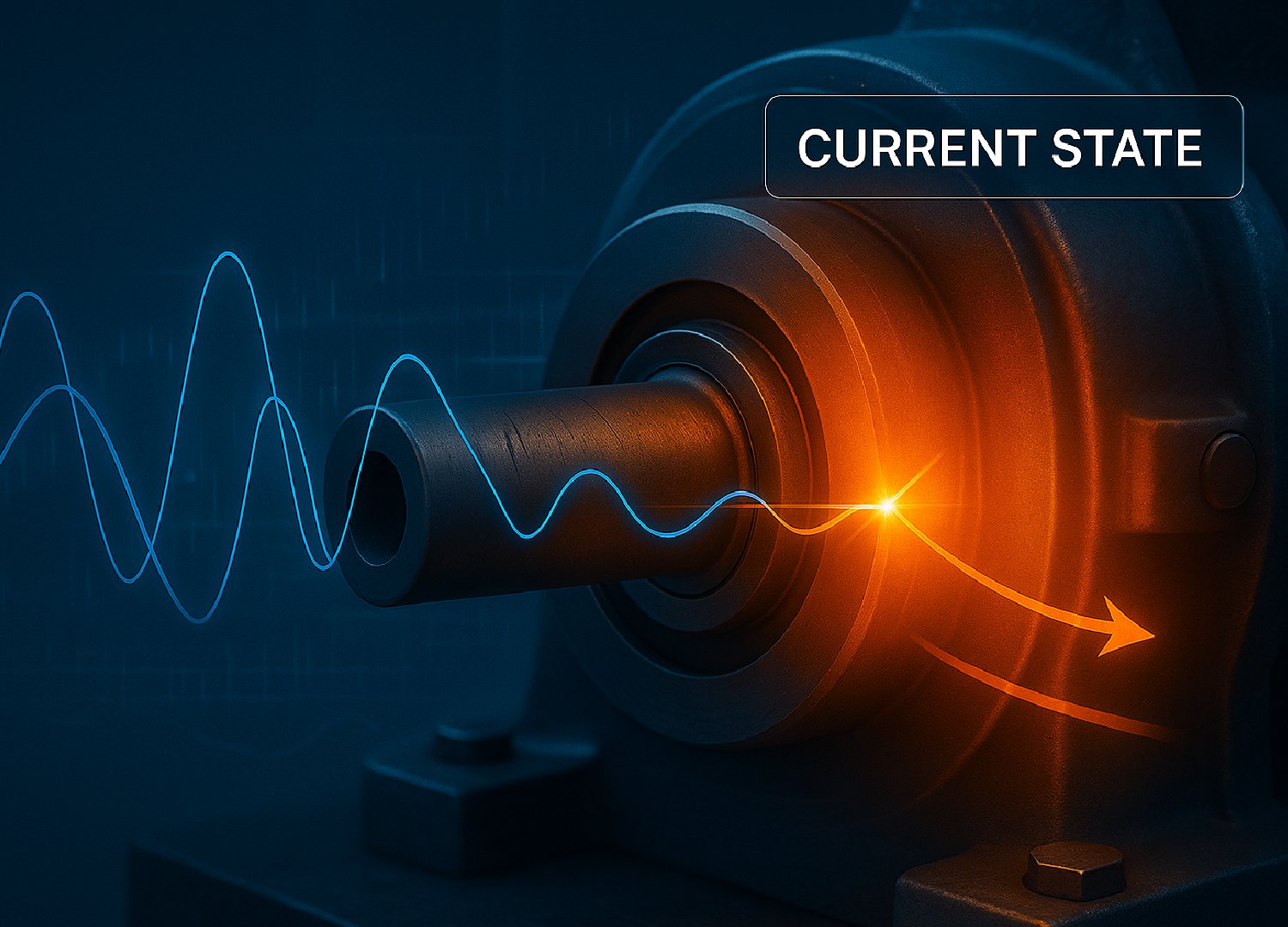

Descriptive Analytics: What's Happening Now?

Sensei captures real-time readings and historical trend data from connected Sensei Devices and Trico Companion Mobile App logged activities. This creates a baseline of normal performance and highlights when and how assets begin to deviate so you always know where things stand.

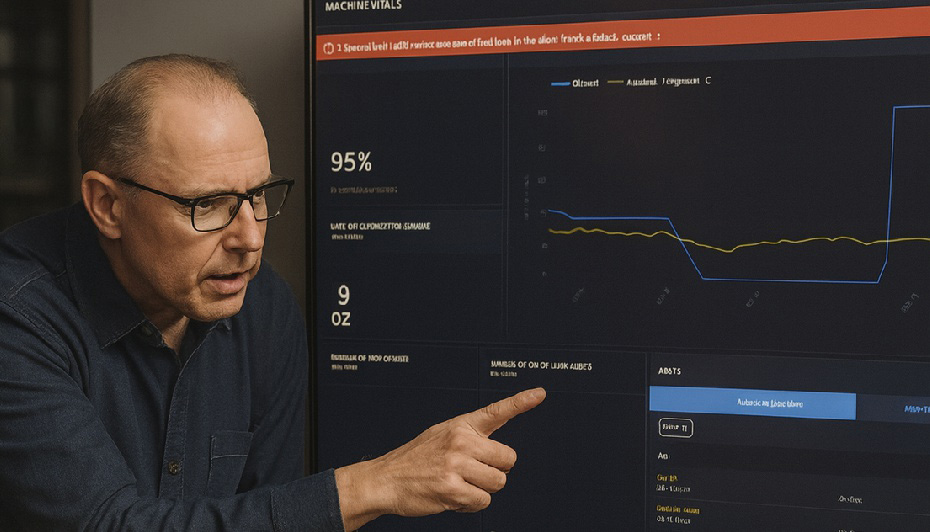

Diagnostic Analytics: Why Did it Happen?

Through root cause indicators and data correlation tools, Sensei pinpoints the triggers behind condition changes. By overlaying readings, such as vibration spikes with temperature increases, you can quickly identify the likely source of an issue and avoid guesswork.

Predictive Analytics: What's Likely to Happen?

Predictive analytics identify patterns that point to what’s coming next. Sensei helps teams anticipate failures, plan maintenance windows, and order parts in advance turning unexpected downtime into scheduled service.

Prescriptive Analytics: What Should Be Done About It?

Insights become clear, from scheduling an inspection to adjusting operating parameters or replacing a component. With Sensei, data collection leads directly to decisive, informed action.

Turning Analysis Into Action

Once analyzed, Sensei’s data becomes the foundation for measurable improvements across your facility.

Equipment Analytics for Every Role

Sensei data analysis empowers every role:

Maintenance Teams

Stay ahead of failures. Analyzed data highlights which assets need attention, helping you prioritize work orders, plan repairs, and confirm the effectiveness of completed maintenance.

Operations

Keep production on track. Operators can see how equipment is performing in real time, validate operating conditions, and report anomalies that help engineers fine-tune processes.

Engineering

Turn insights into improvements. Engineers use trend and cause analysis to optimize system performance, identify process inefficiencies, and support long-term equipment upgrades.

Management

Make decisions with confidence. Management teams can review summarized performance reports, track KPIs, and align budgets and resources with data-backed reliability goals.

Explore the Sensei System

Sensei isn't just a single tool, it's a complete ecosystem that works together to track, transmit, and interpret your equipment data. From smart devices to an intuitive dashboard, each component plays a part in giving you clear, real-time view of your asset health.