Capturing Data Beyond the Surface

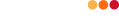

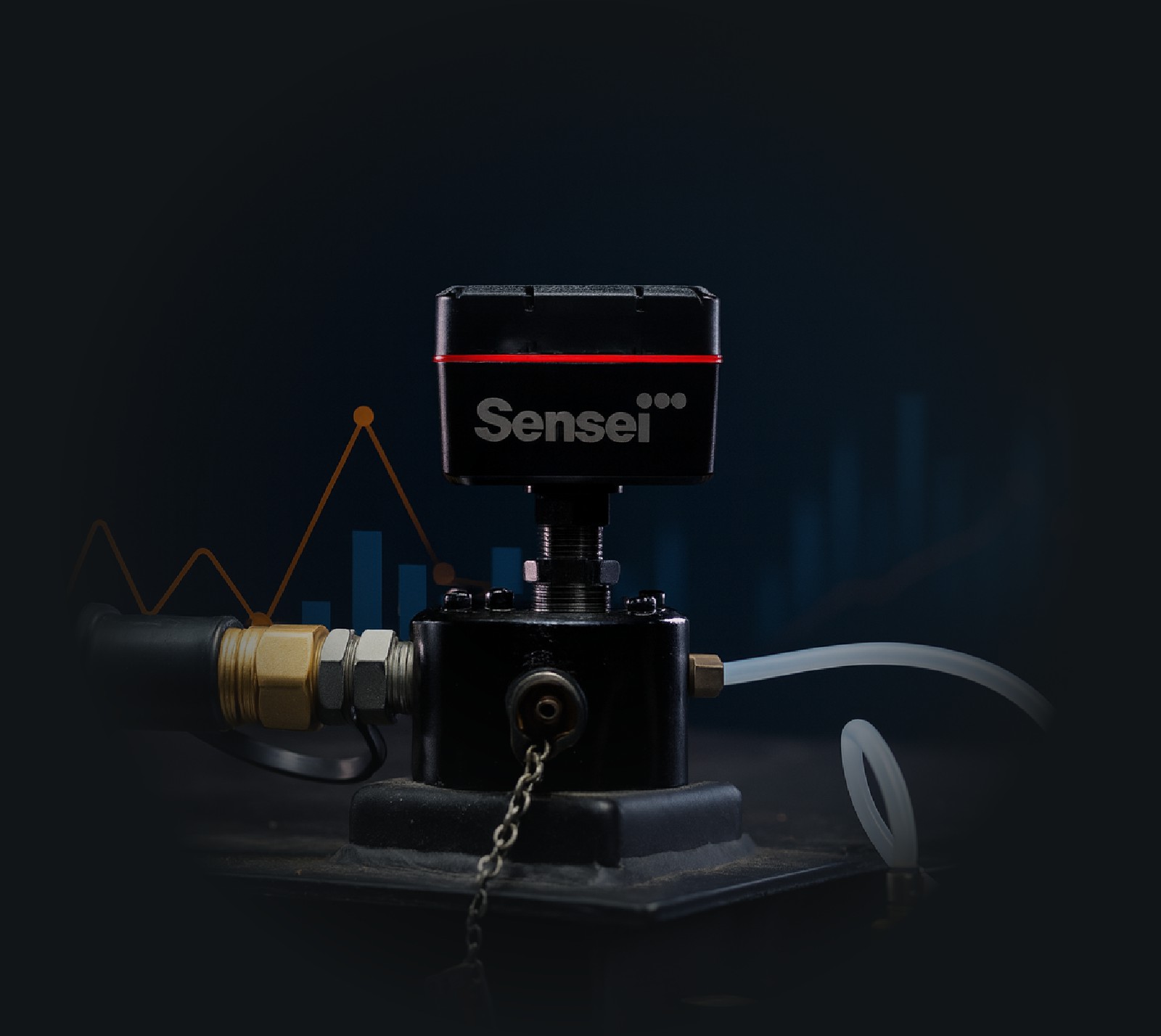

Machine Vitals: Multi-Parameter Condition Monitoring Sensor

Installed above the lubricant headspace, Machine Vitals delivers continuous, real-time visibility into your equipment’s internal and external health. By measuring temperature, humidity, pressure, vibration, and acoustics, it translates subtle changes into clear, actionable insights. The results: earlier detection, more informed maintenance, and fewer unplanned interruptions.

Dual Sensor Technology for Complete Equipment Health Monitoring

See the Full Picture

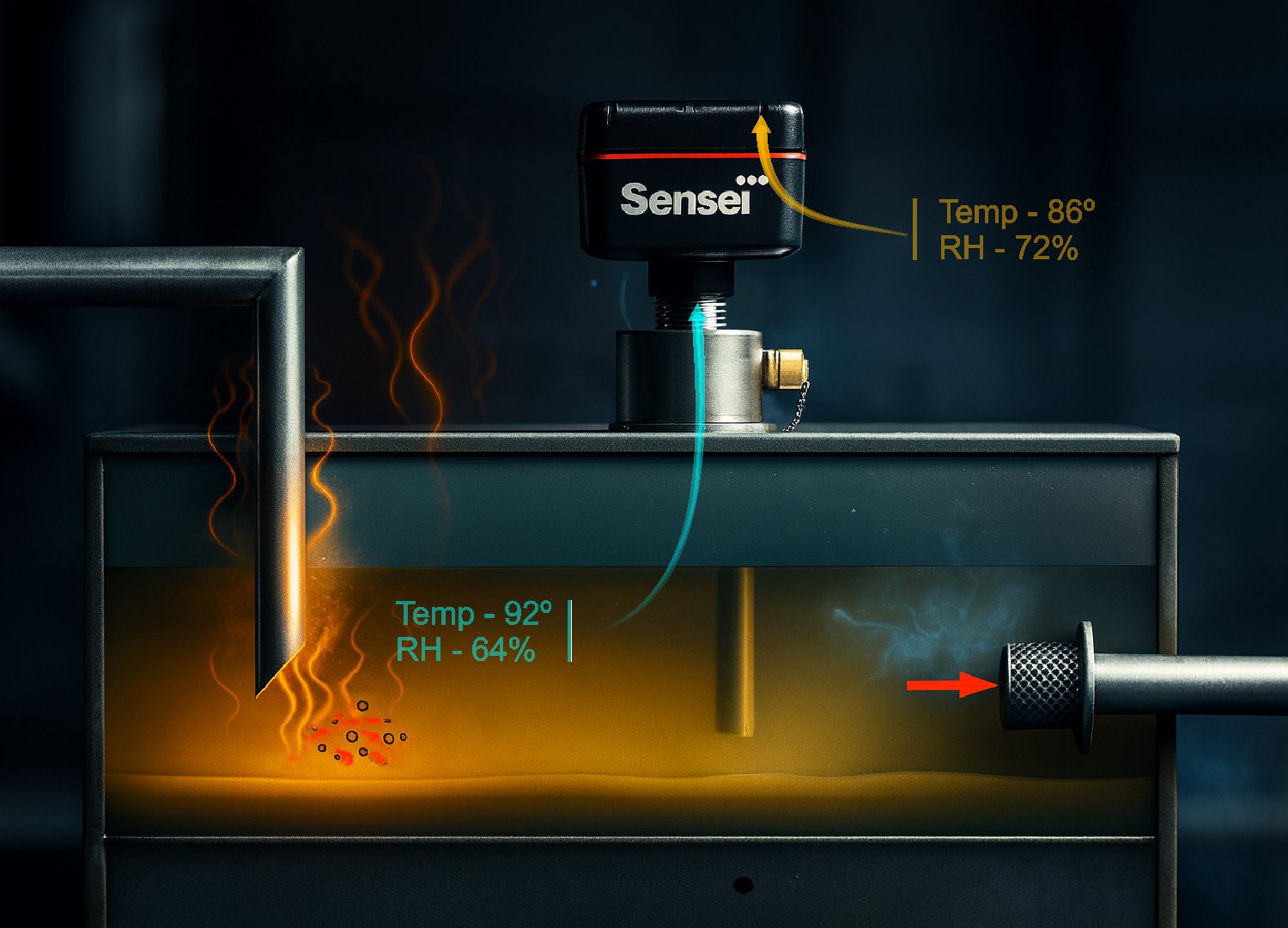

Machine Vitals uses dual sensors to track conditions inside the equipment and surrounding environment, detecting early warning signs before they escalate into failures.

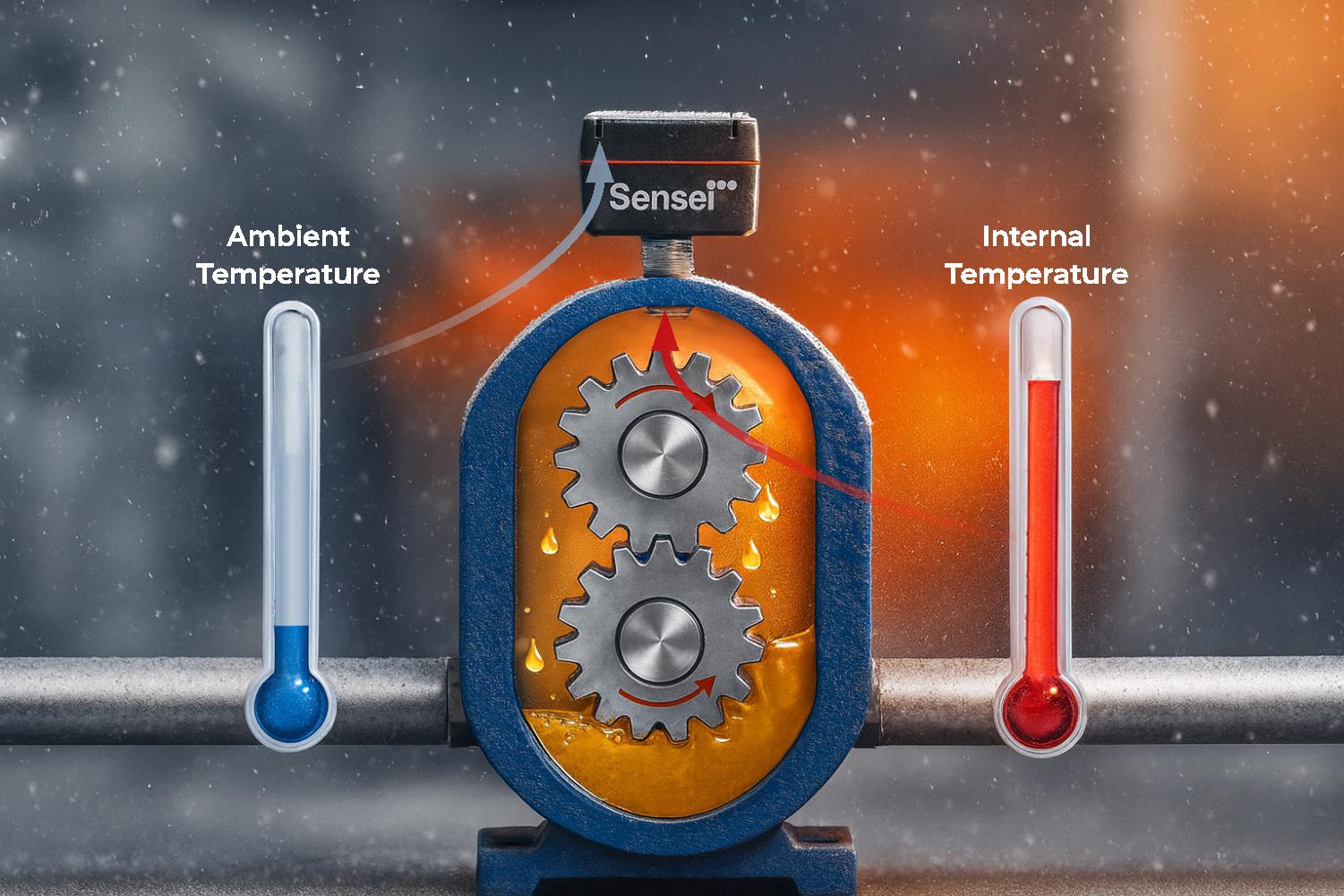

Tracks heat inside the housing to monitor lubrication and component stress, while also monitoring the surrounding ambient temperature that can influence internal conditions.

Monitors internal and external moisture levels to detect ingression, condensation, and risks of corrosion or lubricant breakdown.

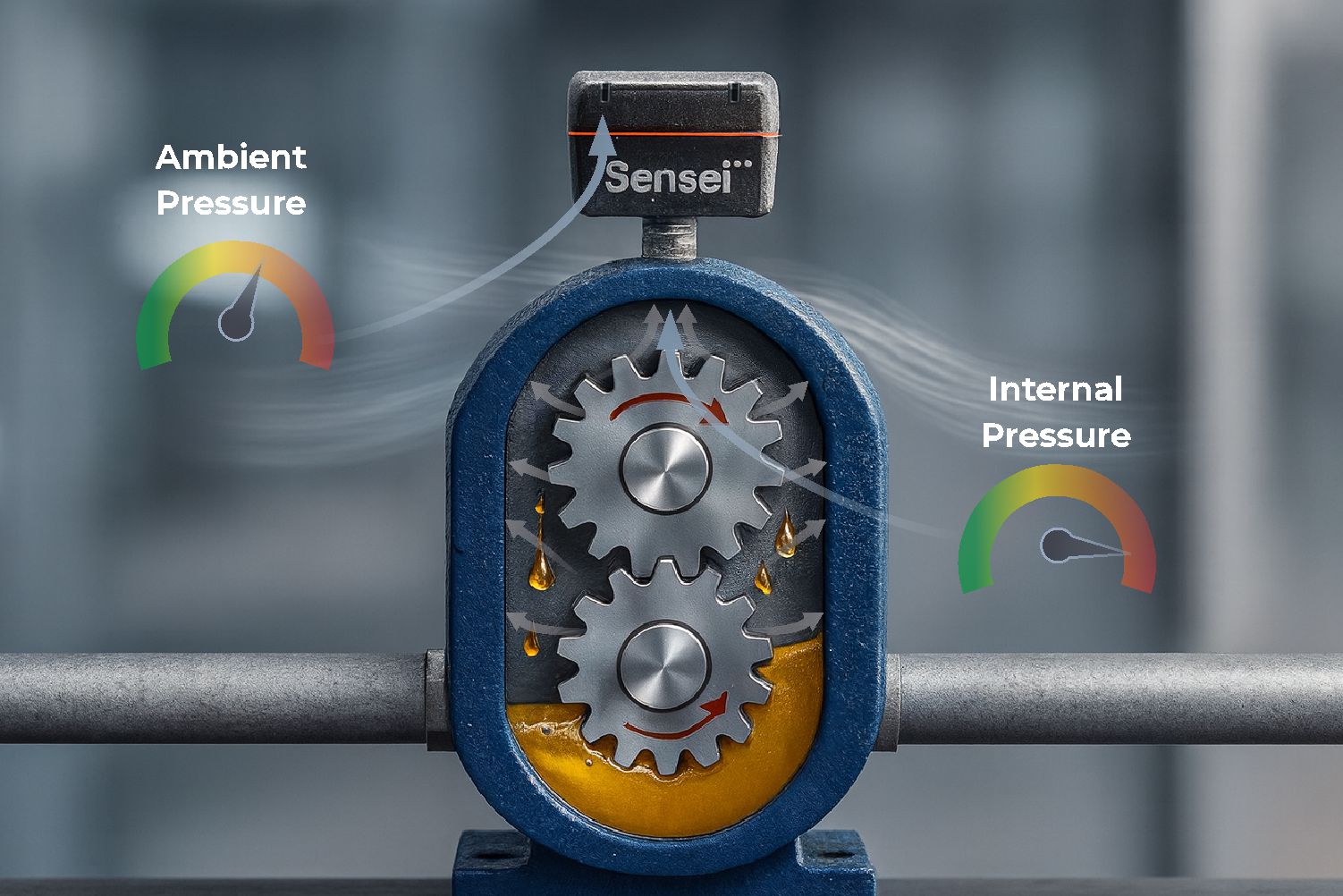

Identifies fluctuations inside the housing and in the surrounding air, identifying external pressure changes, seal issues, or breathing obstructions.

Tracks changes in asset operating behavior such as imbalance or misalignment.

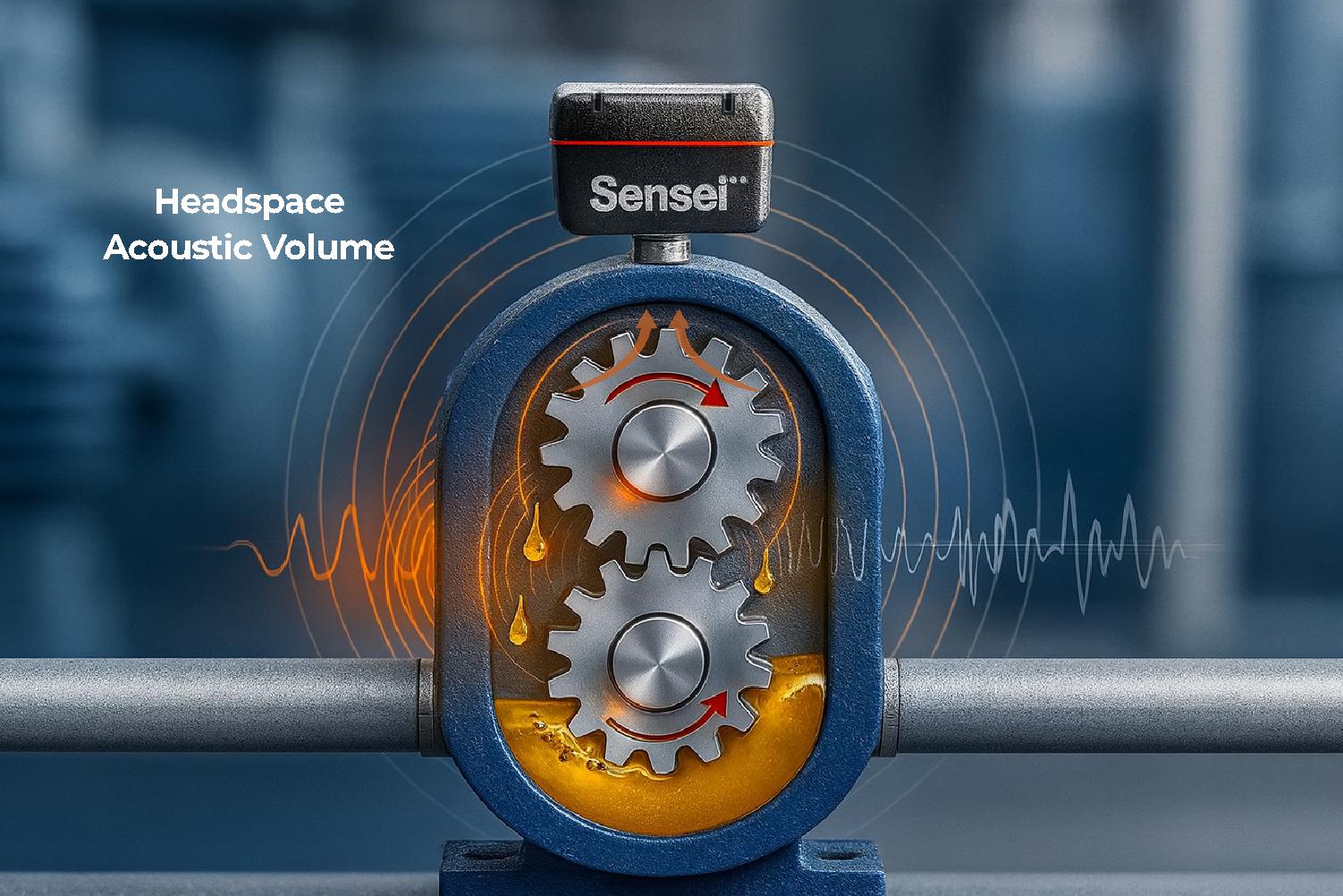

Captures sound patterns that indicate cavitation, looseness, emerging mechanical faults, or other abnormalities.

Beyond Raw Data: Advanced Equipment Condition Monitoring

From its core readings, Machine Vitals calculates derived measurements that reveal hidden risks and provide deeper understanding of equipment health and environment impact.

Remote Equipment Diagnostics and Early Failure Detection

Continuous monitoring translates subtle data shifts into actionable insights; here are just a few examples:

Environmental Contamination Detection

Heat, humidity, or contaminants entering the equipment.

Dual-sensors reveal when environmental conditions like temperature swings, high humidity, or pressure changes begin to migrate into the housing. This allows reliability teams to act before contaminants degrade lubricants and internal surfaces.

Airflow and Ventilation Issues

Restricted air flow in or out of the equipment.

Machine Vitals pressure sensors identify when airflow has changed, signaling a possibility clogged breather or seal failure. This helps maintain stable pressure and temperature, preventing stress on seals and internal components.

Prevent Water-Driven Wear

Internal moisture forming inside housing.

Internal humidity monitoring detects when moisture is inside the equipment. This insight enables intervention before rust, pitting, or water contamination accelerates wear and causes premature bearing or gear failure.

Post-Maintenance Anomaly Detection

Sudden changes after servicing.

By comparing pre- and post-service condition data, Machine Vitals verifies the quality of maintenance work. Any spikes in vibration, temperature, or pressure after service can highlight installation errors, over-lubrication, or missed issues.

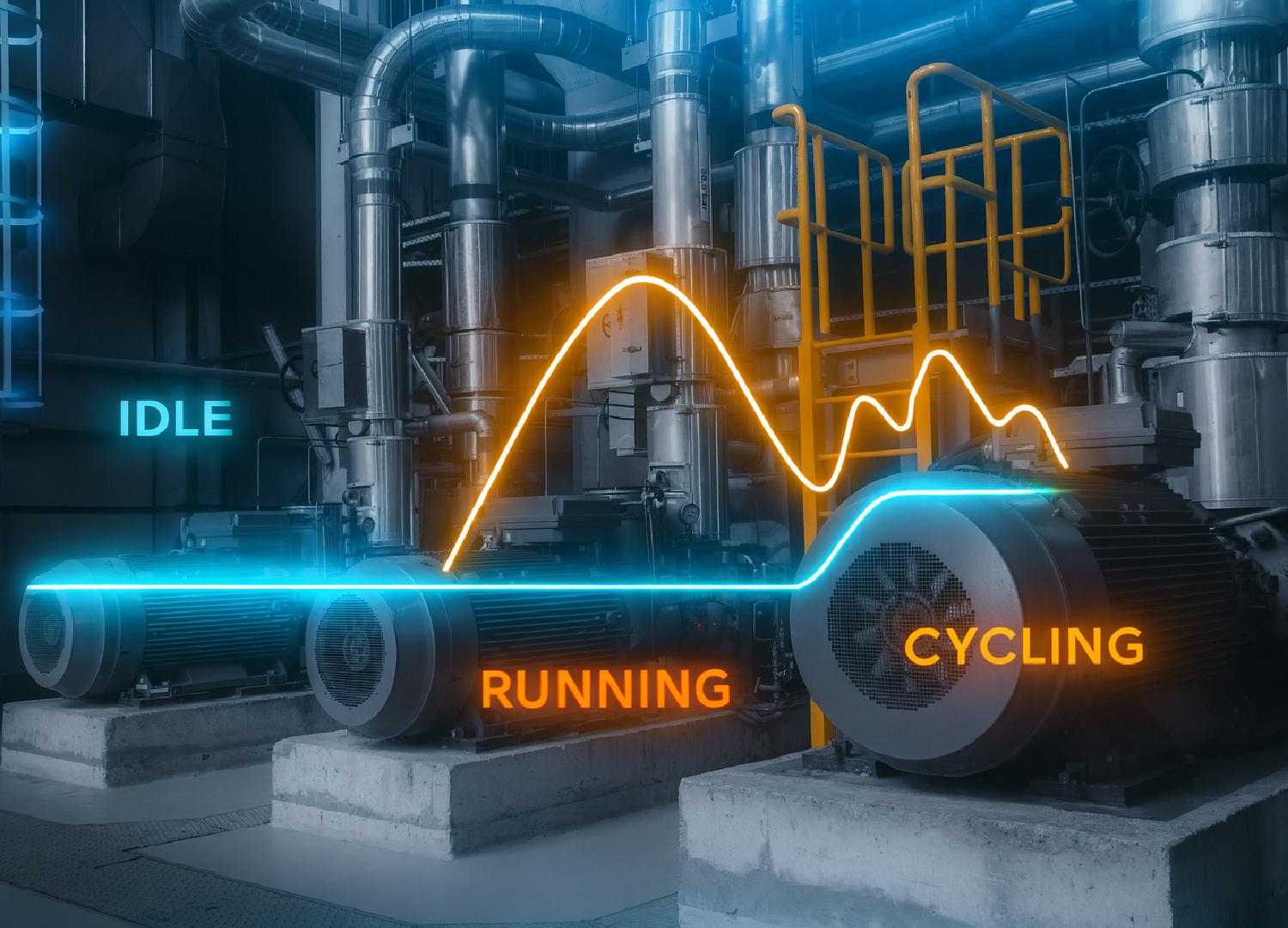

Operational State Changes

Shifts from idle to running or vice versa.

Tracks when machines transition between idle, running, or cycling modes. These insights support maintenance scheduling, energy management, and help confirm operational consistency. Abnormal patterns can signal excessive starts/stops that strain components or onset of future issue.

Mechanical Health Indicators

Vibrations, temperature spikes, or acoustic anomalies.

Real-time vibration, acoustic, and temperature data reveal the subtle shifts that often precede failure such as imbalance, misalignment, cavitation, or overheating. By detecting these anomalies early, teams can schedule part replacements before unplanned downtime hits.

Machine Vitals Benefits: From Sensor Data to Maintenance Action

Machine Vitals drives measurable improvements:

| Benefit | Where It Delivers |

|---|---|

| Time Savings & Efficiency | Remote or hard-to-reach equipment where inspections consume time and resources. |

| Labor Prioritization | Facilities with limited staff or stretched maintenance teams. |

| Data-Driven Decisions | Plants shifting from time-based PMs to condition-based maintenance. |

| Fewer Emergencies | Critical assets where downtime carries high costs. |

| Simplified Maintenance | Pumps or gearboxes in high-production environments. |

| Lower Operating Costs | Large facilities with dispersed assets and high inspection travel. |

| Scalable Monitoring | Multi-area facilities looking for standardization. |

| Compliance & Documentation | Regulated industries requiring full audit trails. |

| Knowledge Capture | Teams with high turnover or training newer staff. |

Additional Features

- 360º Equipment Health View

- Machine Vitals tracks internal pressure, temperature, and humidity while independently monitoring ambient conditions giving you a complete picture of equipment health from the inside out.

- Capture the Smallest Disturbances

- With a built-in IMU sampling at 1,000 times per second, Machine Vitals identifies changes in motion, vibration, or alignment that signal early mechanical faults.

- Sound Diagnostics

- Detecting shifts in noise patterns, Machine Vitals provides another layer of non-invasive diagnostics helping you catch issues that other sensors miss.

- Offline Memory Buffering

- Whether networked or offloaded via Trico Companion Mobile App, Machine Vitals keeps your data safe and accessible. Offline? No problem, it stores data until reconnection.

- Oil Lubricated Equipment

- Installs above the lubricant headspace of pumps, gearboxes, hydraulic units, tanks & storage vessels, and other oil lubricated equipment.

- Tailored Sampling Rates

- Adjust reading intervals or sensor behaviors without pulling the device. Machine Vitals evolves with your operations via secure over-the-air updates.

Other Specs

| Model | Description | Fitting Connection |

|---|---|---|

| 38310 | Machine Vitals Condition Monitoring Device | 1/2" NPT |

-

DimensionsH 3.34” x W 2.63” x L 3.25”

-

Thread Connection½” NPT

-

Power3.6 Volt D Size Battery

-

EnvironmentalIndoor/outdoor use (Designed to IP65)

-

Battery Life3 years (depending on data and frequency settings)

-

Material

Cover: polycarbonate

Base: powder coated aluminum

-

Temperature0°-175° F (-18º to 79ºC)

Customer Testimonials

Frequently Asked Questions About Machine Vitals Condition Monitoring Sensor

Explore the Sensei System

Sensei isn't just a single tool, it's a complete ecosystem that works together to track, transmit, and interpret your equipment data. From smart devices to an intuitive dashboard, each component plays a part in giving you clear, real-time view of your asset health.