Dan Freeland

03.05.2024

Introducing Machine VitalsTM and the Future of IIoT

In our recent discussions, we've highlighted the unstoppable momentum of the Industrial Internet of Things (IIoT). Over the next five years, the integration of IIoT and online sensors within the manufacturing sector is poised to usher in a new era of enhanced efficiency, superior product quality, and groundbreaking innovation. Market forecasts are optimistic, with early-stage online sensing technologies projected to fuel the industrial sensor market to an impressive 40-50 billion dollars in investments within the coming decade..jpg) The extensive data harvested by IIoT and online sensors pave the way for sophisticated analytics and machine learning applications. This wealth of information empowers manufacturers to refine their operations, slash expenses, and elevate the quality of their products.

The extensive data harvested by IIoT and online sensors pave the way for sophisticated analytics and machine learning applications. This wealth of information empowers manufacturers to refine their operations, slash expenses, and elevate the quality of their products. With this backdrop, Trico Corporation is thrilled to unveil the latest addition to our Sensei platform: “Machine VitalsTM.” This sleek, wireless, online sensor is engineered to simplify the monitoring of key data points crucial for assessing the health of equipment and lubricants. By tracking parameters such as temperature, humidity, and pressure, and expectantly integrating these with our Sensei constant-level oilers, users gain a holistic view of their machinery's health.

Trico, with its century-long expertise in industrial lubrication and equipment maintenance, has meticulously selected a broad spectrum of sensory and mechanical indicators. These indicators, which are essential for spotting potential issues, were traditionally gathered through labor-intensive inspections. "Machine Vitals" offers a deep dive into the equipment's core, uncovering minute details within micro-environments and flagging anomalies. It compares external atmospheric conditions with internal metrics, making it easier to spot adverse trends. The Sensei dashboard aggregates data from various sensors, enabling maintenance staff to evaluate equipment performance remotely, and fostering proactive maintenance decisions.

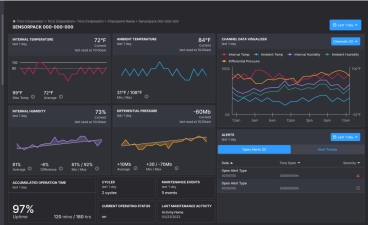

The Sensei dashboard and web application are designed for an intuitive and dynamic user experience, simplifying the process of monitoring and analysis. It features a sophisticated, hybrid navigation structure that merges essential system-defined hierarchies with the option for customized sensor data groupings. This setup supports effortless comparative asset analysis. Users can apply filters to identify variations in performance, alarm frequencies, and types, customizing the data view to fit their needs.

The Sensei dashboard and web application are designed for an intuitive and dynamic user experience, simplifying the process of monitoring and analysis. It features a sophisticated, hybrid navigation structure that merges essential system-defined hierarchies with the option for customized sensor data groupings. This setup supports effortless comparative asset analysis. Users can apply filters to identify variations in performance, alarm frequencies, and types, customizing the data view to fit their needs. For those utilizing Trico's Oil Analysis services, the platform integrates these findings directly onto the dashboard for each sensor-equipped asset, offering a comprehensive overview of all relevant data. This feature enhances decision-making capabilities by providing a visual timeline that links maintenance actions with sensor data.

The platform offers a streamlined overview of all assets, making it easy to prioritize and focus on those with pressing issues, thus ensuring peak operational performance and effective preventive maintenance. Dive into a world where consolidated insights and advanced analytics meet in a user-friendly interface, elevating your asset management practices to new heights.

Jump on the IIoT train today before it runs you over!