Dan Freeland

06.17.2025

Why Filtration is Critical for Gearboxes and Hydraulic Systems

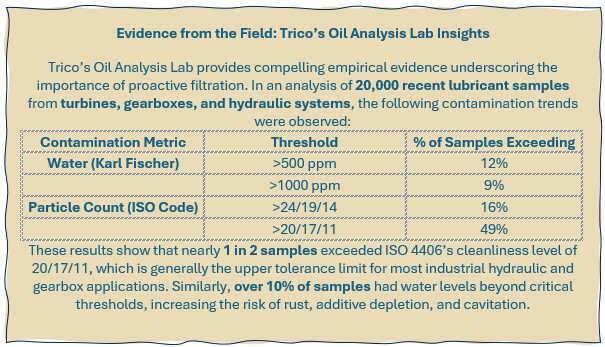

Contamination is a leading cause of failure in industrial gearboxes and hydraulic systems. Particles and water ingress silently degrading components, reducing efficiency, and leading to costly downtime. Investing in proper filtration isn't just preventive maintenance, it's a strategic decision that protects uptime and profitability.

The Hidden Threat: Contamination in Gearboxes and Hydraulics

Gearbox Failures

Contamination accounts for approximately 19.6% of gearbox failures, second only to inadequate lubrication at 34.4%. Common contaminants include dirt, metal shavings, and water, which can enter through worn seals, poor maintenance practices, or environmental exposure. These contaminants accelerate wear, causing pitting and scoring, and compromising gear alignment.

Hydraulic System Failures

Hydraulic systems are even more vulnerable. Studies estimate that 80–90% of hydraulic failures are due to fluid contamination, primarily from water and air ingress. Water contamination leads to corrosion, cavitation, and loss of lubricity, while solid particles cause abrasion and clogging. These issues degrade system performance and can result in catastrophic failures.

The Financial Impact: Downtime and Repair Costs

Gearbox Failures

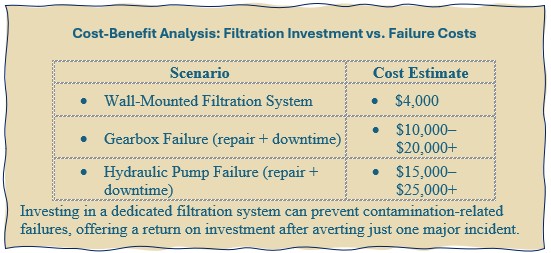

Repairing a failed gearbox can cost between $1,000 and $5,000. However, the associated downtime can be even more expensive. In manufacturing environments, an hour of downtime can result in thousands of dollars in lost production, missed deadlines, and overtime expenses.

Hydraulic System Failures

Replacing a contaminated hydraulic pump can cost up to $15,000, not including the costs of replacing hoses, filters, and other components. Additionally, downtime leads to lost productivity and potential contractual penalties.

Proactive Measures: Implementing Effective Filtration

- Install Dedicated Filtration Systems: Use wall-mounted filtration units to continuously remove contaminants from lubricants and hydraulic fluids.

- Regular Fluid Analysis: Monitor fluid cleanliness and identify contamination early.

- Proper Maintenance Practices: Ensure seals are intact, use clean containers for fluid handling, and follow manufacturer guidelines.

- Environmental Controls: Protect equipment from environmental contaminants by using proper enclosures and seals.

Contamination is a pervasive issue that silently undermines the reliability of gearboxes and hydraulic systems. The costs associated with failures far exceed the investment in proper filtration. By proactively implementing effective filtration solutions, industries can safeguard their equipment, ensure operational efficiency, and achieve significant cost savings.

Be sure to check out this extreme case study delving into the pure costs involved in this critical gearbox failure.