Dan Freeland

08.19.2025

Choosing the Right Setup

One of the most common questions with closed-system (loop) oilers is:“Do I need to use a desiccant vent or diaphragm or can I simply connect the vent line directly to the bearing housing?”

The short answer: it depends on which oiler you choose and how you configure the protective devices around it.

To make it easier, let’s walk through how to pick the right oiler first, then look at the protection options you can add on.

Step 1: Choose Your Closed-Loop (System) Oiler

Opto-Matic Closed-System Oiler

The Opto-Matic Closed-System Oiler is the industry’s workhorse. It provides:- Function: Stable oil level control in a sealed configuration.

- Benefit: Simple, reliable, and highly customizable with breathers, expansion chambers, and Machine Vitals.

- Best Use: Plants comfortable with manual lube routes and visual inspections.

Sensei Enabled Closed-System Oiler

For plants modernizing their lubrication strategy, the Sensei Enabled Closed-System Oiler adds a major advantage: remote monitoring.

- Function: Maintains oil level and continuously reports oil condition status to the Sensei Web Platform

- Benefit: Lube routes no longer take hours. Technicians only respond to flagged low-oil conditions. Management gains visibility into potential oil problems without relying on manual routes or missed checks.

- Best Use: Facilities looking to reduce labor-intensive inspections while improving reliability and accountability.

Step 2: Configure Protective Accessories

Once you’ve chosen Opto-Matic Closed-System Oiler or Sensei Enabled Closed-System Oiler as your base oiler, the second decision is which protective or monitoring devices to add:Water Ingression Scenarios

- Internal condensation or seal ingress - Desiccant breather or passive desiccant cartridge.

- Top-side water spray - Physical exclusion (seals/shrouds) first, then completely closed, or either of the desiccants.

- Pressure imbalance - Desiccant breather (controlled exchange) or Expansion Chamber (volumetric, no exchange).

- These are not paired under normal conditions, except as a backup in case of clogged particle filters in breathers.

- In clean, stable environments, the oiler vent can be piped directly back to the housing for minimal complexity.

- A passive desiccant cartridge + expansion chamber provides both moisture adsorption and pressure relief while maintaining sealed isolation.

- Tracks humidity, temperature, pressure, vibration and acoustics continuously.

- Confirms that your chosen protection method is effective.

- Reports data into the Sensei Web Platform, alongside Sensei Enabled Closed-System Oiler oil level data if both are installed.

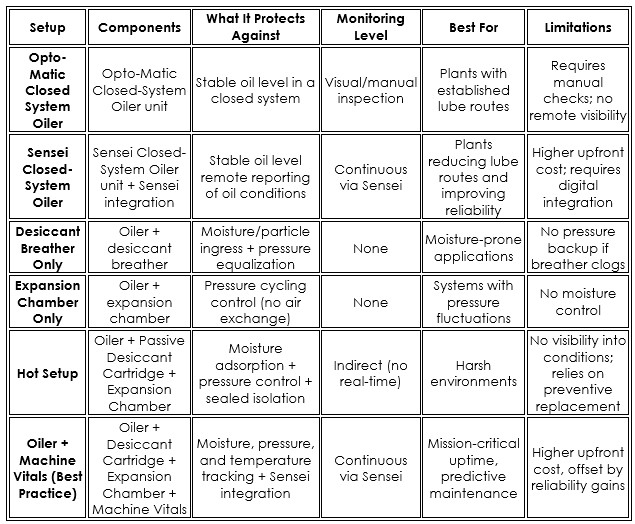

Closed-System (Loop) Oiler Configurations Compared

Key Takeaways

- Closed-System Opto-Matic Oiler - Proven, flexible base oiler for plants relying on lube routes and manual checks.

- Sensei Enabled Closed-System Oiler - Modern closed-system oiler with remote oil level monitoring through the Sensei platform, reducing wasted lube routes and adding management visibility.

- Desiccant Breather Only - Good for moisture control and pressure relief.

- Expansion Chamber Only - Good for pressure cycling, not for moisture.

- Hot Setup - Balanced defense against moisture and pressure.

- Machine Vitals - Adds predictive insight to any setup (Opto-Matic Closed System Oiler or Sensei Enabled Closed System Oiler) by continuously reporting equipment conditions into Sensei.

Bottom line

Your first decision is which oiler fits your plant best: Opto-Matic Closed-System Oiler or Sensei Enabled Closed-System Oiler. From there, you configure the protection level (breathers, expansion chambers, Hot Setups) and decide whether to add Machine Vitals for predictive monitoring. Together, these options move lubrication from a manual chore to a modern reliability strategy.Not sure which setup is right for your plant? Contact us and we’ll help you configure the best closed-loop oiler solution for your needs.