Dan Freeland

11.04.2025

What You Let in Determines How Well You Run

We filter so much in our daily lives.The furnace filters that keep our homes comfortable.

The water filters that make our water taste just right.

The air filters that let our cars breathe easily.

Even the humble coffee filter teaches us something, life’s better when you keep the grounds out.

So why, when it comes to the lifeblood of our equipment, would we ever skip the filter? After all, the same rule applies in industry and in life: what you let in determines how well you run.

Clean Oil, Clear Thinking

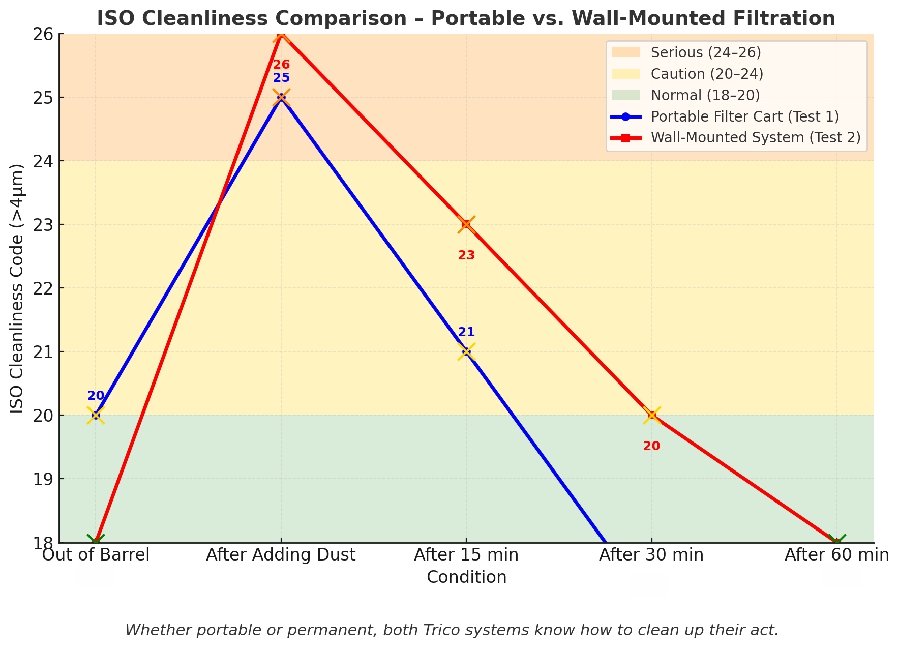

Oil is more than a lubricant, it’s a lifeline. When it’s clean, equipment runs smoothly. When it’s dirty, everything grinds to a halt, literally.Recently, we ran two comparative tests to show how effectively Trico filtration can restore contaminated gear oil. The results didn’t just prove a point about oil cleanliness they revealed a small truth about patience, process, and filtering out what doesn’t belong.

Test Setup

Two systems, same challenge: turn contaminated oil back into a healthy operating fluid. Each system started with 8 gallons of ISO 460 Mobil XP 600 oil. We added 15 grams of Arizona test dust (0–40 µm) to simulate a worst-case contamination scenario. Samples were taken over a period and analyzed for particle counts in Trico’s Oil Analysis Laboratory.Filtration Systems Comparison

| System | Filters | Setup Summary |

|---|---|---|

| Portable Filter Cart (Model 36970) | (2) 10 µm primary filters + (2) 3 µm secondary filter | Designed for speed and depth, rapid flushing or oil transfer. |

| Wall-Mounted Filtration System (Model 37002) | (1) 10 µm primary filter + (1) 3 µm secondary filter | Designed for steady, continuous cleaning, kidney-loop reliability. |

Understanding ISO Cleanliness

We followed the ISO 4406:2017 particle count standard, the industry’s way of quantifying oil cleanliness. It measures the number of particles larger than 4 µm, 6 µm, and 14 µm per milliliter of oil, reported as a three-number code (like 26/25/21).Each jump in the code represents roughly a doubling of particle concentration:

ISO Cleanliness Code Chart

| ISO Code | Particles per ml (approx.) |

|---|---|

| 12 | 20 – 40 |

| 13 | 40 – 80 |

| 14 | 80 – 160 |

| 15 | 160 – 320 |

| 16 | 320 – 640 |

| 17 | 640 – 1,300 |

| 18 | 1,300 – 2,500 |

| 19 | 2,500 – 5,000 |

| 20 | 5,000 – 10,000 |

| 21 | 10,000 – 20,000 |

| 22 | 20,000 – 40,000 |

| 23 | 40,000 – 80,000 |

| 24 | 80,000 – 160,000 |

| 25 | 160,000 – 320,000 |

| 26 | 320,000 – 640,000 |

| 27 | 640,000 – 1,300,000 |

| 28 | 1,300,000 – 2,500,000 |

For both tests, we started by contaminating the oil with 15 grams of Arizona test dust (0–40 µm) to create a controlled, “worst-case” scenario. That produced about 244,000 (25) and 428,000 (26) particles per ml, or an ISO code of 26/25/21, firmly in the Serious zone.

Objective: Determine how long each filtration system takes to restore oil cleanliness.

Test #1: Portable Filtration (Model 36970)

Setup:• Equipment: 36970 High Viscosity Filter Cart

• Filters: (2) 10 µm primary filters + (2) 3 µm secondary filters

• Oil: 8 gallons of ISO 460 Mobil XP 600

• Contaminant: 15 g Arizona Dust (0–40 µm)

Filtration Particle Comparison (Set 3)

| Particles/mL | >4µm | >6µm | >14µm | >21µm | >38µm | >70µm | ISO Cleanliness | Rating |

|---|---|---|---|---|---|---|---|---|

| Out of the Barrel | 5103 | 727 | 50 | 15 | 1 | 0 | 20/17/13 | Caution |

| After adding 15g of particle dust | 244292 | 148685 | 25296 | 7408 | 31 | 0 | 25/24/22 | Serious |

| After 15 minutes of filtration | 10458 | 4475 | 633 | 213 | 1 | 0 | 21/19/16 | Caution |

| After 30 minutes of filtration | 999 | 425 | 73 | 21 | 0 | 0 | 17/16/13 | Normal |

With dual primary and dual secondary filters, the portable cart packs twice the filtration surface area — and it shows. Within 30 minutes, the oil was back in the Normal ISO range. That’s a rapid, effective cleanup ideal for flushing gearboxes or pre-filling systems before commissioning.

Test #2: Wall-Mounted Kidney Loop System (Model 37002)

Setup:• Equipment: 37002 Wall-Mounted Filtration System

• Filters: (1) 10 µm primary filter + (1) 3 µm secondary filter

• Oil: 8 gallons of ISO 460 Mobil XP 600

• Same dust load, same lab analysis

Filtration Particle Comparison (Set 2)

| Particles/mL | >4µm | >6µm | >14µm | >21µm | >38µm | >70µm | ISO Cleanliness | Rating |

|---|---|---|---|---|---|---|---|---|

| Out of the Barrel | 2136 | 524 | 45 | 12 | 1 | 0 | 18/16/13 | Normal |

| After adding 15g of particle dust | 428880 | 176659 | 11672 | 1732 | 1 | 0 | 26/25/21 | Serious |

| After 15 minutes of filtration | 72545 | 32144 | 3388 | 812 | 3 | 0 | 23/22/19 | Serious |

| After 30 minutes of filtration | 5486 | 2115 | 134 | 66 | 3 | 0 | 20/18/14 | Caution |

| After 60 minutes of filtration | 2187 | 836 | 93 | 27 | 0 | 0 | 18/17/14 | Normal |

Result:

The wall-mount system achieved the same Normal ISO cleanliness in about 60 minutes, exactly what we’d expect. With a single-stage setup (one primary and one secondary filter), the system is optimized for continuous, not rapid, filtration. It’s built to maintain oil cleanliness over time in a permanent kidney-loop configuration, a steady guardian for critical assets.

Combined Results

Both systems tell the same story:Clean oil happens fast when you have the right filtration and the right system for the job.

- The portable cart delivers speed and deep cleaning, perfect for new gearboxes or pre-service flushing.

- The wall-mounted system delivers steady, continuous protection, ideal for keeping running equipment in top condition.

- Together, they cover the entire oil cleanliness lifecycle from startup to steady state.

The Takeaway

Everyday life runs on filters; air, water, coffee. So why should your gear oil be any different?Clean oil isn’t just maintenance; it’s machine insurance. It protects your assets, extends equipment life, and keeps up time at its peak.

At Trico, we like to think of filtration as the quiet hero of reliability working behind the scenes to remove the unwanted, so your equipment can keep doing what it does best.

Whether portable or permanent, both Trico systems know how to clean up their act.