.jpg)

Dan Freeland

10.12.2021

Taking Small Steps Will Help you in Achieving your Lubrication Program Goals

The fall season brings us many things. The leaves are changing, the weather is changing, its football and deer hunting season, and the anticipation of the holiday season is right around the corner. For many businesses, it also typically brings the annual budgeting process. Most companies are watching their department budgets closely. While some companies will put a freeze on spending until the end of the year, others will allow remaining allocations to be spent. Now is a good time to review your lubrication program for potential expenses for next year’s budget. Now is the time to include those expenses before budgets are approved for 2022. It doesn’t matter where you are in your lubrication program as long as you continue to plan to improve it incrementally. It is rare that a world class lubrication program is developed overnight, it is a continual process. Let’s look at a couple of scenarios in different stages of developing a quality lubrication program and how it can relate to budget planning.

Dead or no program at all –

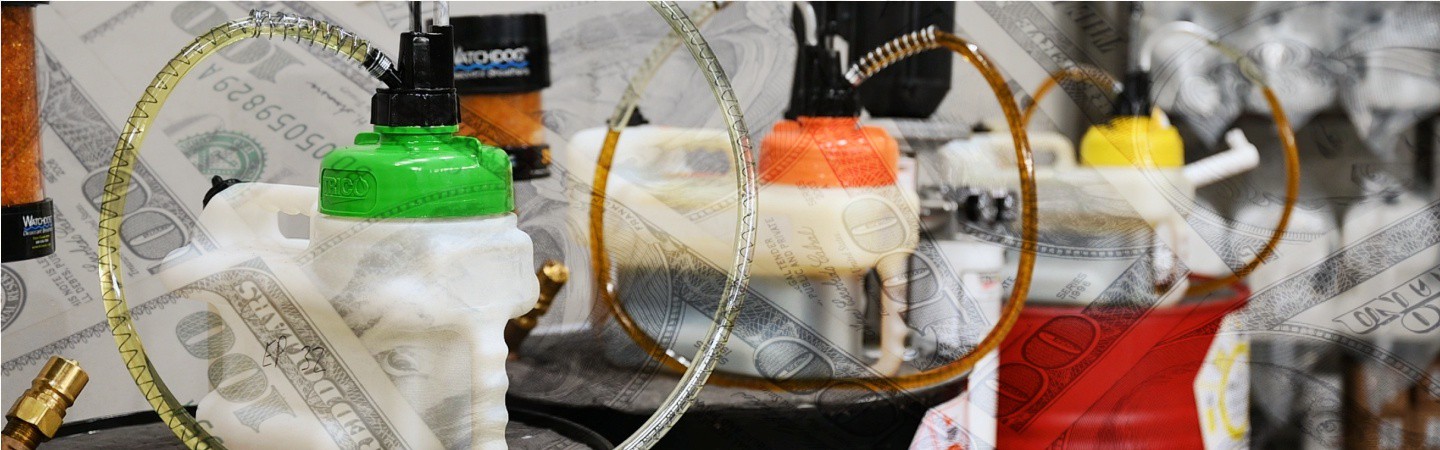

If it is possible, now is the time to get started. If your budget has available resources remaining, take a look at some low hanging fruit that can be obtained for minimal expense. These items can include color coding products such as transfer containers that can be easily implemented and serve as a basic building block to end the year and head into next year with a head of steam. Perhaps it’s upgrading some of your critical equipment from traditional vented oilers to closed systems or even leveraging sensor technology on a trial basis. The point is that lubrication programs are generally the last to receive resources, so if its available, take a step in the right direction. Then, as you lay out your budget you can plan for additional steps or continue building on what you’ve started.

Got the basics –

So, you’ve got the basics covered, but it’s time to take the next step. Look for things that can improve your lube room and your equipment’s health. A portable filtration system purchase could be a low-cost steppingstone for a 2022 filtration program. Again, these types of programs usually start small until the desired results are seen, then more equipment gets added to the program. Choose a piece of equipment, like a gearbox or reservoir, and outfit it with the proper quick connect fittings and get started. If your lube room is comprised of 55-gallon drums, maybe a drum pump filtration system is a quality affordable investment. Begin to filter your oil before transferring to secondary containers. These are incremental steps that will improve your oil’s condition and keep your program moving upward.

Advancing to Oil Sampling and Oil Analysis –

Now is the time to proactively look at your equipment’s health by analyzing the lubricant that keeps it running. Outfitting some of your more critical equipment with oil sampling devices and procuring the sampling bottles and hand pumps will allow you to hit 2022 with the beginnings of an oil analysis program. These oil analysis results can be reviewed with a qualified lubrication program consultant to keep you from realizing unforeseen critical failures in the future. We have potentially saved hundreds of equipment failures from happening by reviewing these results with our customers and defining a planned course of action. Next year’s budget should include some resources for sending a designated number of samples in for analysis.

Let’s Get Started!

This time of year is a great time to reset your lubrication program status and implement small upgrades with an eye on what is it store for your lubrication program. Contact Trico to help you get started.