Filtration

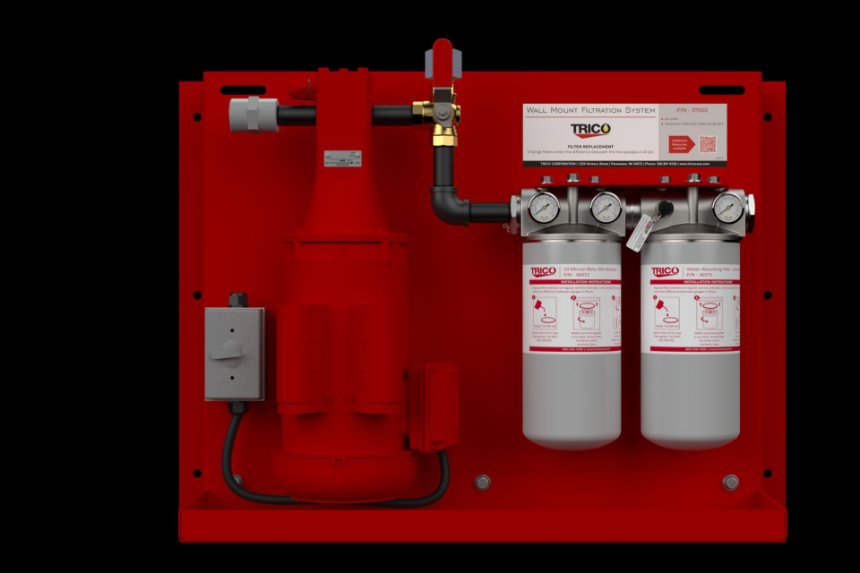

If you’re looking to prevent equipment failure, enhance performance, and gain a competitive edge, start an oil filtration program.

Family of Products

Why do you need Filtration?

Filtration systems make it cost effective to filter out particulate and water contaminants in storage, condition "in service" lubricants, and flush your oil system when necessary.

OEM Requirements

A new lubricant likely does not meet the desired OEM/equipment component’s cleanliness specification right from the start.

Cleanliness

70 percent of all premature machine failures can be attributed to contamination.

.jpg?width=1440&height=450&ext=.jpg)

.jpg?width=1440&height=450&ext=.jpg)