.jpg)

Dan Freeland

01.18.2022

Using Portable Filtration Systems to Remove Contamination

Water is the second most destructive contaminant to cause failures in pumps and gearboxes with particulate being number one. The existence of water modifies the physical and chemical properties of the oil causing common problems such as rust, varnish, and oxidation which eventually attacks and destroys machine components and surfaces.Obviously finding the source of the water contamination would be the first thing you would do. But, if you knew you had a water issue with a piece of equipment, and if you had the ability to remove the water that you knew was damaging your equipment – why would you not do it?

That’s exactly what we did!

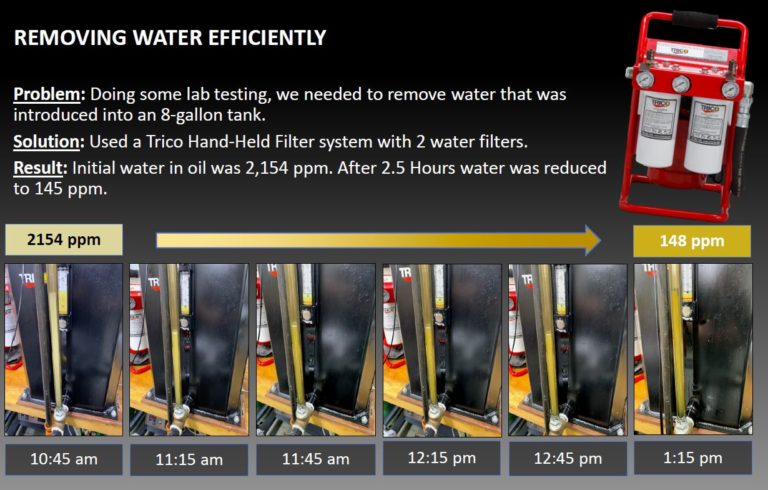

While running some tests in our Engineering lab a couple of months ago, we had a need for a test where water was introduced to an 8-gallon reservoir of ISO 32 mineral oil. After the testing was complete, we saw the opportunity to remove the water from the oil with a secondary test to reconfirm and validate the efficiency of our portable filtration systems. We connected our filtration unit, fitted with (2) 10-micron water filters, to the 8-gallon reservoir.

While running some tests in our Engineering lab a couple of months ago, we had a need for a test where water was introduced to an 8-gallon reservoir of ISO 32 mineral oil. After the testing was complete, we saw the opportunity to remove the water from the oil with a secondary test to reconfirm and validate the efficiency of our portable filtration systems. We connected our filtration unit, fitted with (2) 10-micron water filters, to the 8-gallon reservoir.We started with oil analysis to determine the amount of water in the oil. The result, based on a Karl Fischer test, a whopping 2,154 ppm of water. We turned on the portable filtration system and took pictures of the liquid level gauge on the reservoir every 30 minutes. After 2.5 hours of cycling the oil through the filtration system, we took another oil sample. Again, based on a Karl Fischer test, the water ppm dropped to a minuscule 148 ppm. Looking at the pictures side by side, you can visually see the change in oil clarity.

This was not a huge surprise because the filters did what they were supposed to do – remove water, and they did it very effectively. Applying portable filtration (application) and oil sampling (validation) to your equipment like gearboxes, hydraulic reservoirs, and even large pumps undoubtedly cleans your oil and extends the time between oil changes and your equipment’s life between failures. Simply put…it works.

This was not a huge surprise because the filters did what they were supposed to do – remove water, and they did it very effectively. Applying portable filtration (application) and oil sampling (validation) to your equipment like gearboxes, hydraulic reservoirs, and even large pumps undoubtedly cleans your oil and extends the time between oil changes and your equipment’s life between failures. Simply put…it works.

- Category:

- Contamination