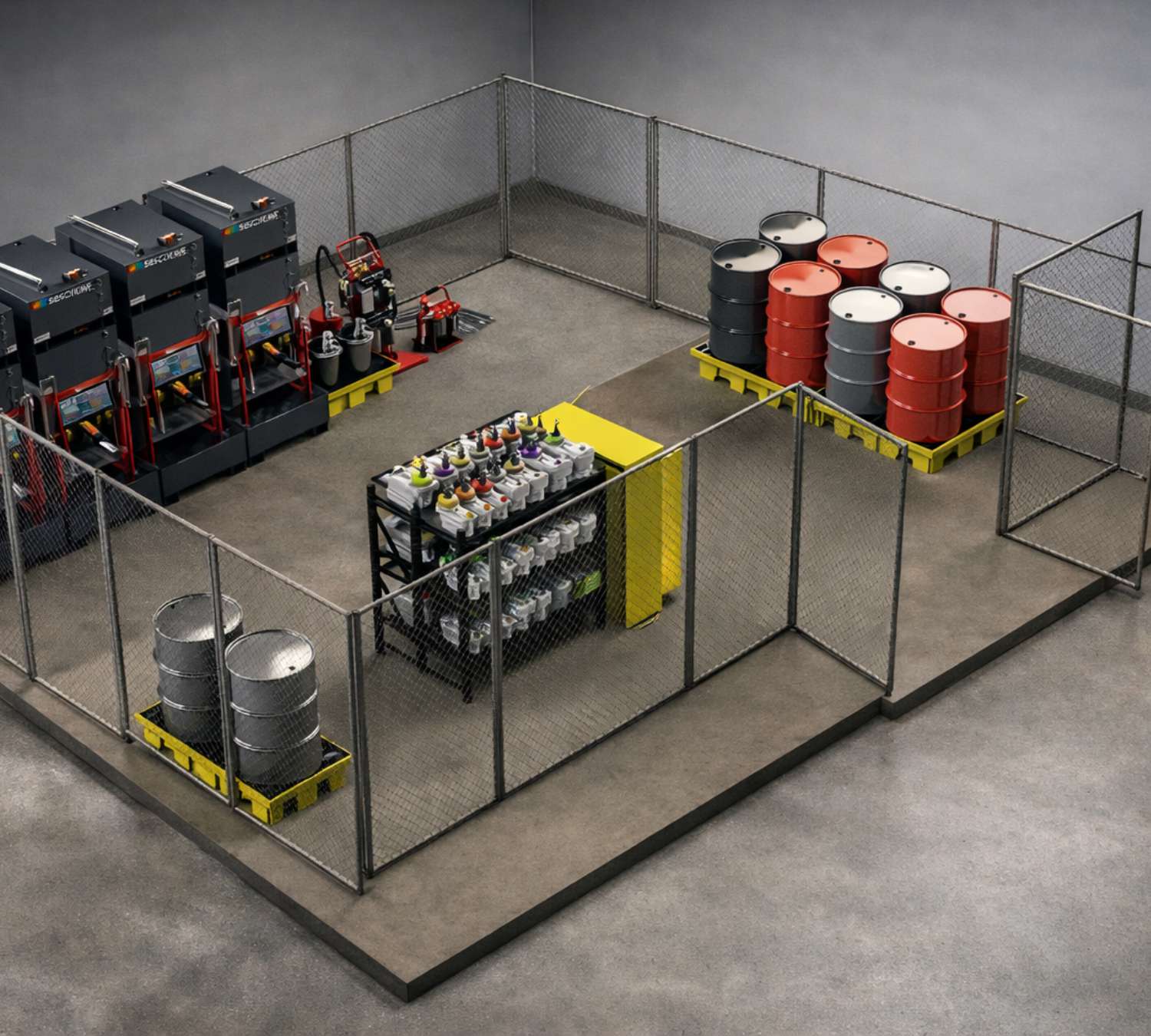

Spectrum Bulk Oil Storage System

Clean storage isn’t optional; it’s the foundation of a reliable lubrication program. Spectrum Bulk Oil Storage Systems give you a controlled way to store, handle, and dispense lubricants so they stay clean, organized, and ready for use. Whether you're moving away from 55-gallon drums or upgrading an existing setup, Spectrum replaces guesswork with a defined, best practice workflow.

Watch Video

Contamination Control

Protects lubricants from moisture and contamination

Decluttered Storage

Eliminates drum clutter and uncontrolled storage

Clear Identification

Improves identification and workflow clarity

Consistent Handling

Standardizes lubricant handling across your plant

Built for Scalability

Scales easily as your lubricant needs growFamily of Products

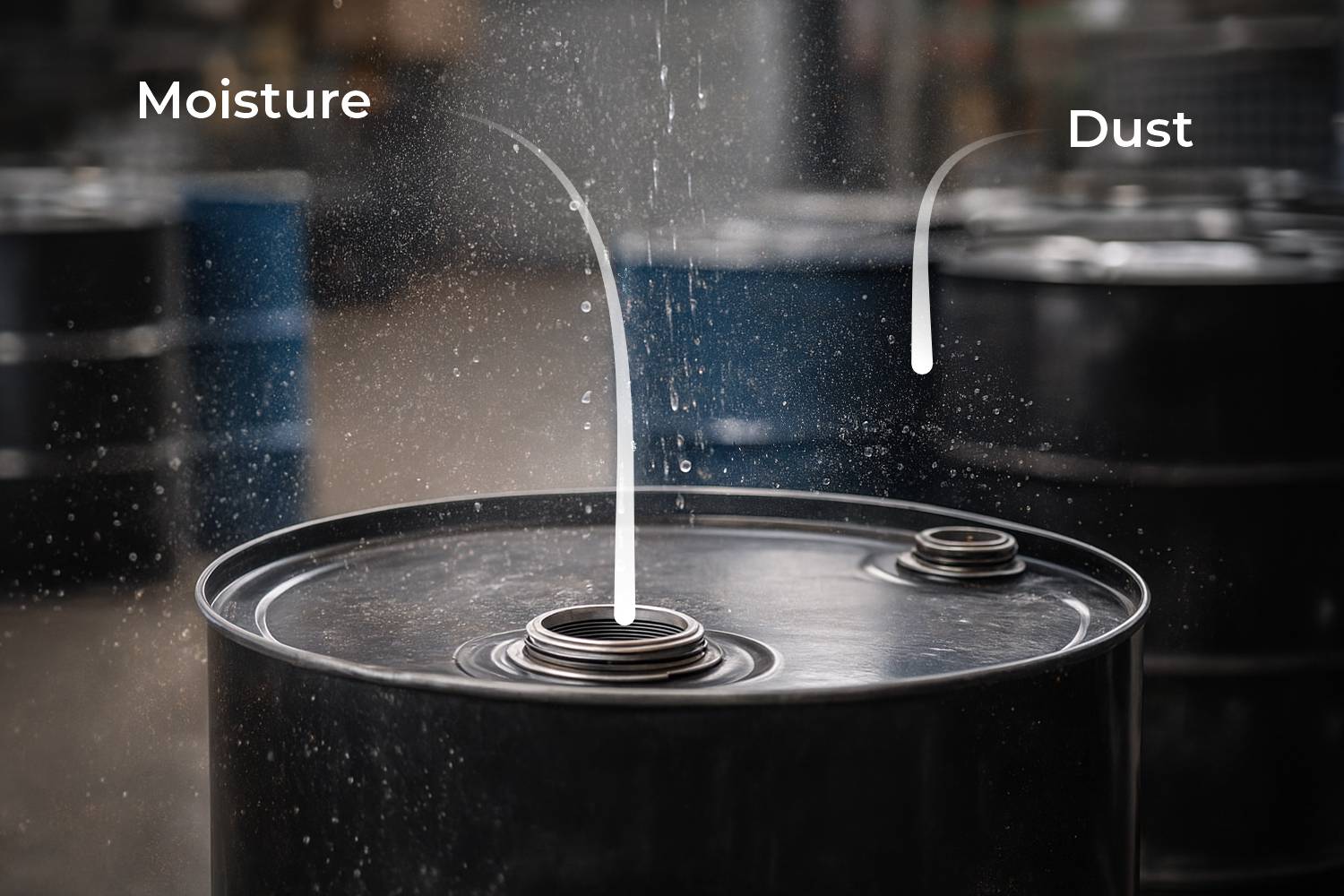

Hidden Risks

Contamination Starts Earlier Than You Think

Most contamination enters oil before it ever reaches a machine. Oil drums and totes allow moisture, dust, and debris to enter every time they’re opened. Poor labeling, scattered containers, and uncontrolled transfer methods only make things worse, turning storage into one of the most overlooked failure points in lubrication programs.

A structured storage system eliminates these variables. By controlling the storage environment, facilities reduce cross-contamination, improve oil cleanliness, and deliver a repeatable handling process that supports long-term reliability.

Built for Reliability

A Clean, Consistent Process for Storing and Dispensing Lubricants

Spectrum replaces ad-hoc oil storage with a system built around sealed tanks, organized dispensing, clear identification, and modular expansion. Instead of 55-gallon drums, open containers, and inconsistent top-offs, Spectrum gives your team a standardized, best-practice approach that stays consistent across departments and facilities.

This is the first step in contamination free life cycle, from the moment oil enters your plant to the point of use.

What Every System Has in Common

All Spectrum Bulk Oil Storage Systems share a common platform engineered to protect lubricant integrity and streamline handling. This consistency makes it easier to establish best practices across plants and locations.

Built to handle real plant conditions and daily use.

Designed to reduce risk and support regulatory compliance.

Protecting lubricant cleanliness before it ever reaches the machine.

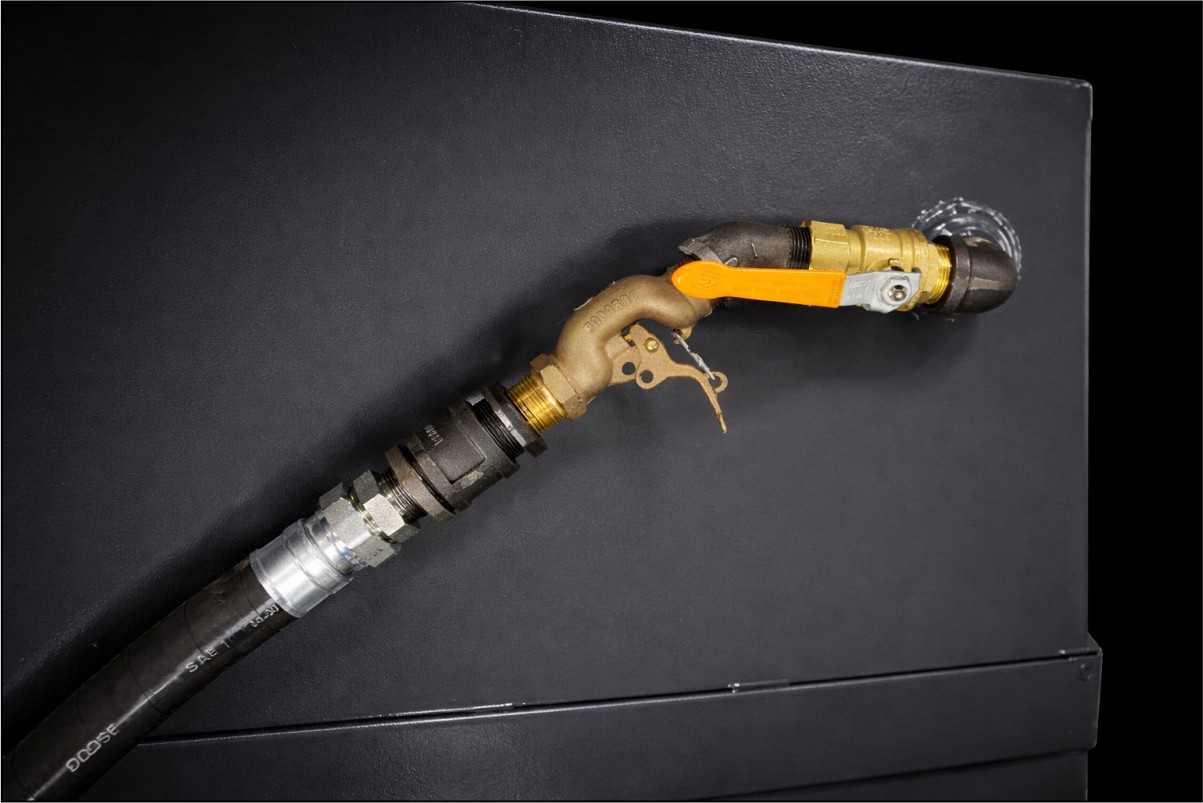

Control over how and when oil moves through the system.

Reducing the chance of cross-contamination and misapplication.

Easy to implement, easy to reposition as your layout changes.

Designed for Central Lube Rooms and Satellite Locations

Build for Your Space, Not Around It

Spectrum Bulk Oil Storage Systems are compact, mobile, and fully assembled making them easy to deploy in existing lube rooms or as satellite stations near equipment. Start with one stack or build a full storage wall. As needs change, additional stacks can be added seamlessly without redesigning your space.

Configure Your Requirements

Options for Safety, Visibility, and Compliance

Enhance your system with add-ons that support site-specific standards and operational needs.

Support site safety standards.

Enhanced visual level indication

Additional labeling, hose management, and documentation accessories.

Why Do You Need Spectrum Bulk Oil Storage Systems?

Spectrum Bulk Oil Storage Systems give you a defined, repeatable way to store, organize, and handle lubricants. By replacing open drums and improvised storage, you reduce risk, eliminate inefficiencies, and support a cleaner, safer workflow.

Reduces Space

Compact, vertical tank stacks free up valuable floor space and remove drum clutter from lube rooms and maintenance areas.

Prevents Cross-Contamination

Color-coded tags, labels, and sealed tanks ensure the right lubricant goes into the correct tank, transfer container, and machine every time.

Eliminates Safety Hazards

A closed, stable system reduces the risks associated with maneuvering, tipping, or stacking 55-gallon drums, supporting safer handling at every step.