Dan Freeland

07.18.2023

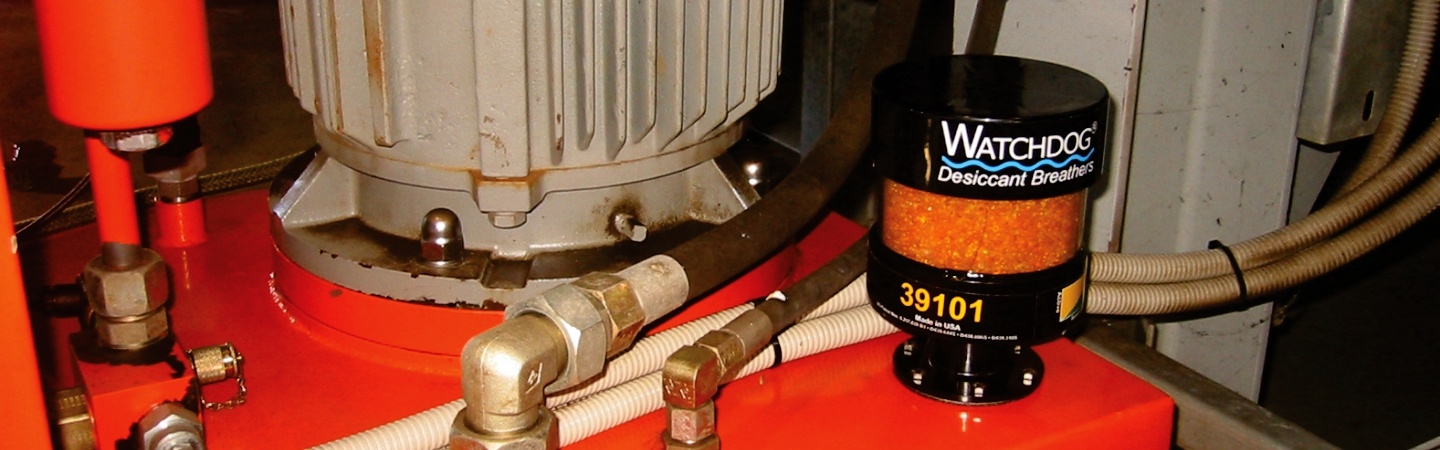

Combat Summer Humidity with Top-Quality Desiccant Breathers

Summertime might be the most awaited season of the year as it brings forth long-awaited vacations, beach trips, and outdoor activities. But with the sun comes humidity, which can have detrimental effects on your equipment. High humidity can cause moisture ingression inside equipment, giving rise to corrosive environments resulting in reduced productivity, and even equipment failure. The high humidity levels of summer and fall seasons make it essential to optimize your Desiccant Breathers to effectively battle moisture ingression. Keeping your equipment in optimal working condition year-round should be among the top priorities for Reliability Engineers, Maintenance Managers, and Technicians. In this article, we will talk about how using Desiccant Breathers can help combat the overwhelming humidity and why it is crucial to check them regularly during the summer season.

Preventing Moisture Ingression

Desiccant Breathers products have been designed to keep your equipment operating at peak levels by removing moisture from the headspace of the equipment. These systems provide a cost-effective solution to moisture ingression, extend equipment life, reduce maintenance costs, and lower downtime caused by equipment failure. Most industrial companies have implemented the use of Desiccant Breathers but using them correctly is key to optimizing effectiveness. The high humidity levels during the summer season make it even more critical to check and replace them regularly to avoid costly maintenance and repair downtime.

Moisture ingression inside equipment can lead to various problems. When moisture gets inside your equipment, it can create a corrosive environment that can deteriorate the equipment's internal components leading to unexpected breakdowns or even complete failure. Moreover, moisture can cause oxidation of the oil, forming sludge and varnish depositions which cause significant damage to machinery. By installing Desiccant Breathers, you can fight against moisture contamination by removing moisture from your equipment headspace, keeping them dry and critical components safe from rust and corrosion.

Desiccant Breathers are highly effective in removing moisture from headspaces; however, it is also essential to have the right capacity. It is essential to match the equipment’s air exchange rate and capacity with the required breathing rates while maintaining the lowest pressure drop resulting in maximum operational efficiencies. This helps make sure that your equipment’s headspace is in an optimal range, free from moisture contamination. Additionally, it is imperative to inspect and replace the Desiccant Breather regularly, ensuring that it remains at peak performance during critical summer and fall seasons.

The summer season is characterized by wide temperature swings, which generate a lot of moisture in the air during the morning hours. This can have devastating effects on your equipment, especially when it is not operational. While the equipment is not in use and it's left to sit idle, moisture ingression can increase as the temperature drops inside the equipment, forming condensation. This can lead to oil contamination and accelerated rust and corrosion. To mitigate these effects, it is essential to use advanced technology Desiccant Breather systems that operate efficiently during such conditions, helping to ensure your equipment is in optimal condition and ready for its next operation.

Battling Large Temperature Swings

Optimizing your equipment's Desiccant Breather is key when it comes to battling the rising humidity levels during the summer and fall seasons. By removing moisture, you can extend the life of your equipment, and avoid costly downtime, and unplanned maintenance that can be detrimental to your overall operations. Choosing the right Desiccant Breather systems, matching their capacity to equipment, regularly inspecting, and replacing them, is crucial to keep them in peak working condition every day, year-round. Take care of your equipment, and it will take care of you while helping ensure maximum production, efficiency, and equipment life.

_______________________________________

**PRODUCT UPDATE 2/1/2024**- Trico is excited to share enhancements across our desiccant breather product line, now featuring both orange/green and blue/pink desiccant options. The EX-series breathers check valves are shielded, ensuring they remain free from clogs and stickiness upon exposure. Additionally, the Particulate Filter is 3-microns crafted from dual-phase micro-glass for superior filtration. The updated Watchdog Desiccant breathers have a versatile “tri-fit” connection, compatible with 1-inch or 3/8-inch male threads, adaptable for NPT, BSPT, or BSPP standards. Discover the new and improved Watchdog Desiccant Breathers today!