Watchdog Extreme Humidity Desiccant Breathers

In environments with extreme humidity, the lubricants and other fluids stored in various equipment need desiccant breathers to remove water vapor and solid particles. However, small temperature variants can draw in humid air and unnecessarily reduce the life of the breather. The Watchdog® Extreme Humidity Breathers incorporate check valves. The addition of check valves is ideal for low-flow and intermittent operations in high humidity conditions.

Feature

Check Valves

Feature

Tri-Fit Connection

Special Feature

Desiccant Color Options

Blue or Orange

Our blue desiccant changes from blue to pink, signaling moisture saturation and ensuring easy monitoring. The orange desiccant shifts from orange to green, providing a clear indication of its condition. Both options are designed to offer superior moisture absorption, with the choice between them often guided by specific environmental, safety considerations, industry needs, and/or personal preference.

Feature

Installation Date Label

Additional Features

- Water Vapor Adsorbent

- The silica gel used in the Watchdog Extreme Humidity Breathers adsorbs up to 40% of its own weight.

- Visual Indication

- When maximum adsorption is reached, the silica gel changes color, indicating replacement is needed.

- Center Tube

- The center tube is made from durable nylon material, which gives the element rigidity and ensures uniform airflow through the silica gel.

- Durable Construction

- Watchdog Extreme Humidity Desiccant Breathers are manufactured from rugged ABS plastic.

- Dual Filtration System

- A dual layer of filter media is located at the top of the silica gel bed. This serves a dual purpose: it effectively prevents the migration of silica dust while also capturing oil mist. Additionally, it ensures even distribution of air across the filter media and the silica gel.

Other Specs

| Model | Description | Air Flow | Water Capacity | Silica Gel Color | Height | Diameter | Connection | Fluid Volume Exchange |

|---|---|---|---|---|---|---|---|---|

| WB-040205-EX | Low Air Flow EX Breather | 5 CFM | 28 ml or 0.06 lbs | Blue | 4.14" | 2.54" | 3/8" Tri-Fit MNPT, BSPT, BSPP | 37 gpm or 142 lpm |

| WB-040627-EX | High Air Flow EX Breather | 27 CFM | 272 ml or 0.6 lbs | Blue | 4.40" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 202 gpm or 765 lpm |

| WB-050205-EX | Low Air Flow EX Breather | 5 CFM | 60 ml or 0.13 lbs | Blue | 5.59" | 2.54" | 3/8" Tri-Fit MNPT, BSPT, BSPP | 37 gpm or 142 lpm |

| WB-060410-EX | Low Air Flow EX Breather | 10 CFM | 143 ml or 0.31 lbs | Blue | 6.11" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WB-070626-EX | High Air Flow EX Breather | 26 CFM | 500 ml or 1.10 lbs | Blue | 6.50" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 194 gpm or 736 lpm |

| WB-080410-EX | Low Air Flow EX Breather | 10 CFM | 264 ml or 0.58 lbs | Blue | 8.28" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WB-090625-EX | High Air Flow EX Breather | 25 CFM | 728 ml or 1.60 lbs | Blue | 8.60" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 187 gpm or 708 lpm |

| WB-100410-EX | Low Air Flow EX Breather | 10 CFM | 424 ml or 0.93 lbs | Blue | 10.38" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WB-110624-EX | High Air Flow EX Breather | 24 CFM | 958 ml or 2.11 lbs | Blue | 10.70" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 179 gpm or 680 lpm |

| WG-040205-EX | Low Air Flow EX Breather | 5 CFM | 28 ml or 0.06 lbs | Orange | 4.14" | 2.54" | 3/8" Tri-Fit MNPT, BSPT, BSPP | 37 gpm or 142 lpm |

| WG-040627-EX | High Air Flow EX Breather | 27 CFM | 272 ml or 0.6 lbs | Orange | 4.40" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 202 gpm or 765 lpm |

| WG-050205-EX | Low Air Flow EX Breather | 5 CFM | 60 ml or 0.13 lbs | Orange | 5.59" | 2.54" | 3/8" Tri-Fit MNPT, BSPT, BSPP | 37 gpm or 142 lpm |

| WG-060410-EX | Low Air Flow EX Breather | 10 CFM | 143 ml or 0.31 lbs | Orange | 6.11" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WG-070626-EX | High Air Flow EX Breather | 26 CFM | 500 ml or 1.10 lbs | Orange | 6.50" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 194 gpm or 736 lpm |

| WG-080410-EX | Low Air Flow EX Breather | 10 CFM | 264 ml or 0.58 lbs | Orange | 8.28" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WG-090625-EX | High Air Flow EX Breather | 25 CFM | 728 ml or 1.60 lbs | Orange | 8.60" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 187 gpm or 708 lpm |

| WG-100410-EX | Low Air Flow EX Breather | 10 CFM | 424 ml or 0.93 lbs | Orange | 10.38" | 4.10" | 1" Tri-Fit MNPT, BSPT, BSPP | 63 gpm or 238 lpm |

| WG-110624-EX | High Air Flow EX Breather | 24 CFM | 958 ml or 2.11 lbs | Orange | 10.70" | 5.70" | 1” Tri-Fit FNPT, FBSPP, FNPSM | 179 gpm or 680 lpm |

-

Check Valve Capacity.1 psi in/out

-

Particulate Filtration Level3-micron absolute

-

Operating Temperature Range-20º to 200ºF / -28 to 93ºC

-

Silica Gel AdsorptionUp to 40% of its own weight in water

-

MaterialABS, Nylon, Polypropylene, and Buna

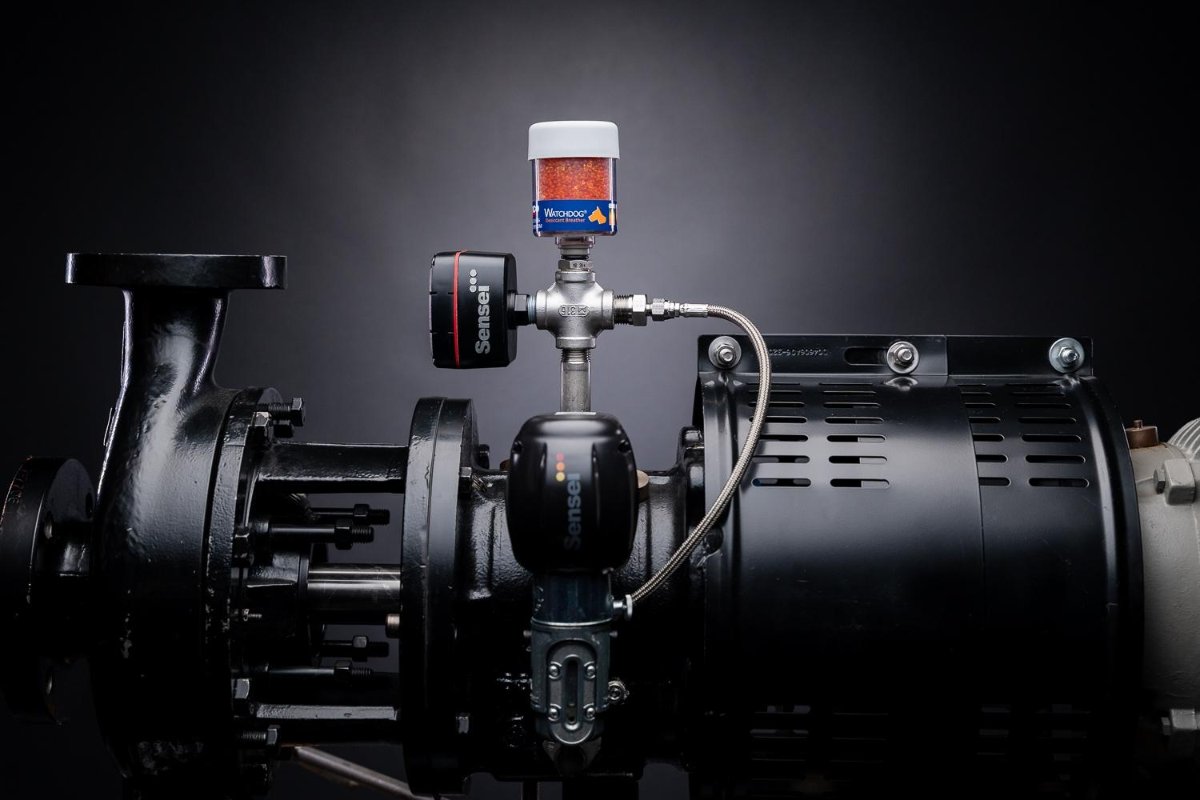

Smart Monitoring, Smarter Maintenance

Breathing Easy with Machine Vitals

Machine VitalsTM, part of the Sensei® IIoT Network, is a condition monitoring device designed to track several key equipment conditions, such as temperature, pressure, relative humidity, and more, providing a holistic view of machinery health. When used in conjunction with Watchdog Desiccant Breathers, Machine Vitals can significantly enhance the effectiveness of your maintenance strategy. By continuously monitoring the conditions that desiccant breathers are designed to mitigate—specifically moisture contamination—Machine Vitals offers a data-driven approach to assess the breather's performance.

This synergy allows for precise determination of when a breather is nearing the end of its useful life, based on real-time data. This not only ensures that machinery is protected from moisture but also optimizes the replacement schedule for Watchdog Desiccant Breathers, ensuring they are only replaced when necessary. The integration of Machine Vitals with Watchdog Desiccant Breathers offers a proactive maintenance solution that keeps equipment running smoothly, reduces downtime, and extends the lifespan of both the machinery and the breathers themselves.