.jpg)

Dan Freeland

09.06.2022

Filtering Incoming Oil – part 2

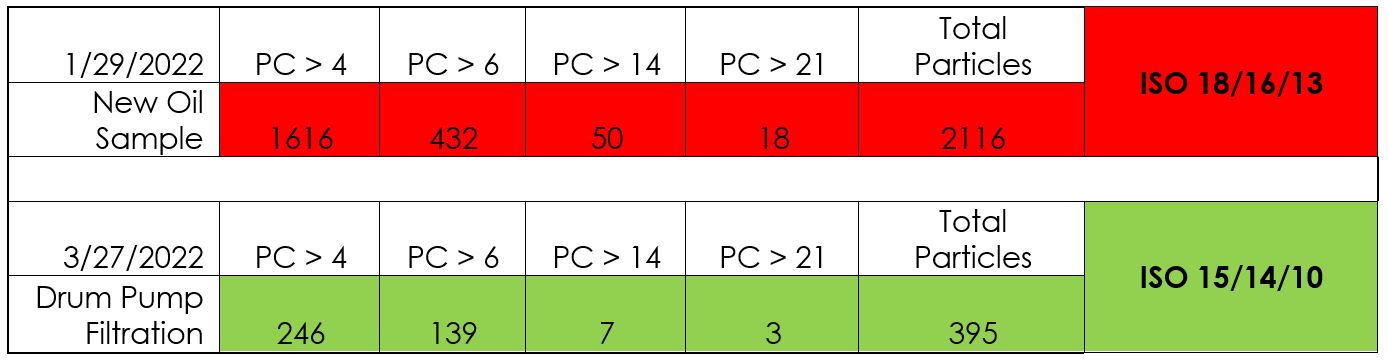

In the last article we talked about the importance of taking an oil sample when you receive your new oil. This is just another recent example of finding out what condition your oil is in before it is put into service, and another way to address oil that may not be up to application standards.When reviewing the samples of oil sent into us by a large power generation facility, we noticed the sample from a new oil. The oil sample was from a new 55-gallon drum of AW ISO 68. This lubricant is specifically designed “for high pressure hydraulic systems operating under moderate to severe conditions in mobile and industrial service”. That’s typical of many hydraulic lubricants. You would expect the particle count in the drum to be in a range these types of applications demand. Depending on which chart you reference, these applications are in the ISO 16/14/12 area, with ISO 18/16/13 the bare minimum. In this case we’re looking for around ISO 15/13/10.

Since this oil was going into some critical equipment, we wanted to make sure we had quality oil up to the performance we are expecting from this equipment. We asked the customer to use the Drum Pump Filtration system they had purchased from Trico to kidney loop filter the new oil for approximately 1 hour. The drum pump flow rate is 6-7 GPM and we want 7 passes through the filter. So, 55 gallons through the filter 7 times is 385 total gallons. 385 total gallons divided by 6 gallons per minute is 64 minutes.

The results were as follows:

.jpg)

By reducing the particulate content from ISO 18/16/13 down to ISO 15/14/10 we can say the hydraulic equipment life has been extended by a factor of 2x. That’s theoretical of course as many other factors can affect equipment life, BUT that’s quite a return on investment of 1 hour of filtering the oil before using it straight out of the drum. Filter first – expect more.