Jim Jung

09.15.2020

Effects of Pressure and Vacuum in Bearing Housings – Constant Level Oilers

It is widely known that some industrial equipment, specifically bearing housings, breathe when in operation. There are several reasons for this. Most of the time, it is the continuous balance of air pressure within the housing and the external atmospheric pressure. If a pump is starting up, the air in the headspace above an oil bath begins to heat up. This is because the bearings, the oil and pump casing are heating up. When air heats up it expands, thus the need for the bearing housing to expel air from it. This is more pronounced the greater the difference in external air temperature to the bearing housing air. Conversely, when the equipment shuts down, the headspace air cools, as the air cools it contracts pulling air into the housing.

Where Does Air Exchange Occur?

There are a couple ways this headspace air exchanges with the outside atmosphere. The simplest way for this to happen is through a vent, goose-neck pipe (J-Tube), or ideally a desiccant breather. Some bearing housing shaft seals use a labyrinth path for air exchange. Others provide a labyrinth path that opens by a dynamic O-ring while running but closes this path when cooling down. Lip seals are designed to “burp” at 3-5 psi but does allow for pressure build up if not otherwise vented. Magnetic seals are hermetically sealed and do not provide any air exchange.

What Happens When Pressure Builds Up?

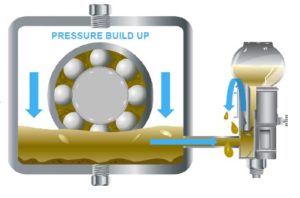

Air pressure can build up in a bearing housing for several reasons. One, is that the fill port is closed with a plug. Additionally, the shaft seals are not exchanging any air. Either they are tight lip seals, magnetic seals, or could be labyrinth seals that become defective due to installation. As air pressure increases in the housing, the air expands effectively pressing down on the oil bath. If there is a vented constant level oiler installed, this pressure can force oil out of the bearing housing up through the oiler, and out on to the floor.

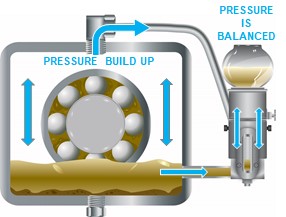

To alleviate any pressure build up, install a vent, or better yet, a desiccant breather in the fill port (a desiccant breather will prevent the ingression of contaminants as your system breathes). Alternately, a closed system constant level oiler will balance this pressure between the oiler and bearing housing.

When Does a Negative Pressure Occur?

A negative pressure or vacuum can be created in a bearing housing as well. This happens typically when there is a goose-neck pipe (J-Tube, or vent installed in the fill port. It takes a very small air flow moving across that pipe or vent opening to create a venturi effect, causing a vacuum in the bearing housing. This can happen regardless of the shaft seal type. When the vacuum is created, it will pull oil straight out of a vented constant level oiler. If you have ever watched any vented constant level oiler feed out over and over, knowing there’s enough oil in the bearing housing, this vacuum is what’s happening. There is also the possibility that the air flow is created by a fan (i.e. pump motor or bearing housing affixed to a fan), that air flow runs straight down the shaft, through the seals and out through a vent or opposite seal, creating a vacuum inside the bearing housing. This will drain a vented constant level oiler as well. To alleviate any vacuum situation that drains your oiler, use a desiccant breather instead of a vent. Or better yet change your vented oilers to the closed system constant level oiler.

Get a Breath of Fresh Air

Most equipment needs to breathe, however if they are not properly equipped problems will occur. To control these problems the use of closed system oilers, desiccant breathers, or ideally a combination of both will allow your equipment to breathe when necessary. An important added benefit is that they will reduce the ingression of moisture and particulates into your equipment.

VIDEO: Watch a video on installing a closed system oiler with a desiccant breather.

Not Sure What Solution You Need?

We can help assist you with the right solution for your application.

_______________________________________

**PRODUCT UPDATE 2/1/2024**- Trico is excited to share enhancements across our desiccant breather product line, now featuring both orange/green and blue/pink desiccant options. The EX-series breathers check valves are shielded, ensuring they remain free from clogs and stickiness upon exposure. Additionally, the Particulate Filter is 3-microns crafted from dual-phase micro-glass for superior filtration. The updated Watchdog Desiccant breathers have a versatile “tri-fit” connection, compatible with 1-inch or 3/8-inch male threads, adaptable for NPT, BSPT, or BSPP standards. Discover the new and improved Watchdog Desiccant Breathers today!