Victoria Bunchek

03.16.2021

Direct Reading Ferrograph Testing is WEAR it’s at

What is it?

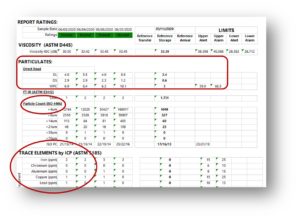

Used in the analysis of in-service oil, the Direct Reading Ferrograph is a trending instrument – providing readings that measure the number of metallic particles, both large (DL) and small (DS) in an oil sample. The DL focus is on particles greater than 5 microns in size and the DS focus is on particles less than 5 microns in size. The DL and DS numbers of the Direct Reading Ferrograph are added together to determine the wear particle concentration (WPC). The power of the DR testing is not in a one-time test. The power of the DR data comes from the trend you create over time. By taking samples of your equipment’s oil on consistent basis, a story emerges about how many harmful wear particles are present. If a spike occurs in this trending analysis, it is an indication something has happened to your equipment to create many more wear particles than “normal” for that equipment. This warning allows maintenance and operations to plan for preventive maintenance before catastrophic failure occurs.

and the DS focus is on particles less than 5 microns in size. The DL and DS numbers of the Direct Reading Ferrograph are added together to determine the wear particle concentration (WPC). The power of the DR testing is not in a one-time test. The power of the DR data comes from the trend you create over time. By taking samples of your equipment’s oil on consistent basis, a story emerges about how many harmful wear particles are present. If a spike occurs in this trending analysis, it is an indication something has happened to your equipment to create many more wear particles than “normal” for that equipment. This warning allows maintenance and operations to plan for preventive maintenance before catastrophic failure occurs.

Use with Other Tests for the Complete Picture:

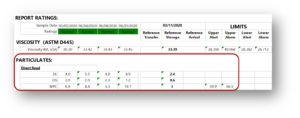

- Particle Count Tests – As particles in the oil flow past a laser, the light is blocked, allowing individual particles to be counted and sized. The resulting data is a distribution of the concentration of particles in various size ranges. These particles consist of ferrous and non-ferrous particles including non-wearing particles such as air bubbles, lint, and tiny bugs. The DR test focuses specifically on wear particles in a range of damaging sizes.

- Inductively Coupled Plasma (ICP) Spectroscopy – This instrument tests a specific volume of energized lubricant using an electrical arc. The light frequencies and intensities are measured and reported in parts per million of various elements. The elements make up wear debris, additives, and contamination. However, these are very tiny particles, less than 8 microns. This test does not account for larger potentially damaging wear particles, greater than 8 microns, where the DR testing does.

Focusing on Wear Particles

Coupling these three tests – ICP, Particle Count, and Direct Reading Ferrography will provide you with the most complete picture of the particles in your oil. But, if you want to focus on the damaging ferrous wear particles specifically, focus on the time-based trending of the WPC from the DR – and watch for the spikes.

For additional information on the set-up and operation of the Direct-Reading Ferrograph watch our video.

- Category:

- Oil Analysis

- Application