Dan Freeland

10.10.2023

The Flexibility and Conditions for Opto-Matic® Oiler Placement Relative to Shaft/Bearing/Flinger Rotation

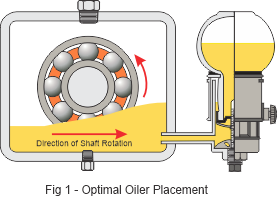

The placement of the Opto-Matic Oiler in relation to the direction of shaft, bearing, and flinger rotation is traditionally considered crucial for optimal performance (Fig.1). However, practical experience and operational conditions have shown that the oiler can function efficiently even when mounted on the opposite side, given certain considerations. This blog post explores this flexibility while acknowledging the need for situational awareness regarding specific operational conditions.

The placement of the Opto-Matic Oiler in relation to the direction of shaft, bearing, and flinger rotation is traditionally considered crucial for optimal performance (Fig.1). However, practical experience and operational conditions have shown that the oiler can function efficiently even when mounted on the opposite side, given certain considerations. This blog post explores this flexibility while acknowledging the need for situational awareness regarding specific operational conditions.

Introduction

While it is generally advised to mount the Opto-Matic Oiler in alignment with the direction of rotation for ideal performance, it should be highlighted that this is not an absolute requirement for effective functionality. Under various conditions, the oiler has been observed to perform reliably even when mounted on the opposite side, providing that specific operational factors are considered.

The Direction of Rotation and Oiler Placement: A Balanced Perspective

Ideal vs. Alternative Placement

Though Trico's official guidelines recommend that the oiler be installed on the side of the bearing housing that corresponds with the rotation direction, experience shows that mounting on the opposite side can also result in successful operation, subject to certain conditions.

Though Trico's official guidelines recommend that the oiler be installed on the side of the bearing housing that corresponds with the rotation direction, experience shows that mounting on the opposite side can also result in successful operation, subject to certain conditions.

Operational Conditions: Startup and Continuous Operation

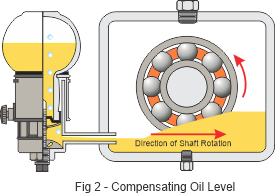

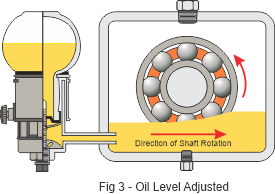

When the oiler is placed on the side opposite the direction of rotation, it compensates for the oil swell, (Fig. 2 - oiler feeding, air bubbles visible in oiler reservoir) thus still adequately maintaining the oil level (Fig. 3). This flexibility in mounting position allows for a broader range of installation options, provided one is aware of the specific conditions in which the machinery operates.

When the oiler is placed on the side opposite the direction of rotation, it compensates for the oil swell, (Fig. 2 - oiler feeding, air bubbles visible in oiler reservoir) thus still adequately maintaining the oil level (Fig. 3). This flexibility in mounting position allows for a broader range of installation options, provided one is aware of the specific conditions in which the machinery operates.

Equipment Shutdown

Even after shutdown, any elevated oil levels due to the direction of rotation are automatically compensated for at the next startup, provided one is aware of this behavior and makes necessary operational adjustments.

Navigating Extreme Conditions

Considerations for Non-Ideal Placement

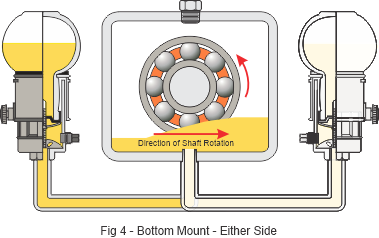

When dealing with larger bearings in smaller housings, multiple flingers, or smaller oiler reservoirs, improper placement may pose challenges. However, even in these extreme cases, effective operation can be maintained by mounting the oiler from the bottom of the bearing housing.

When dealing with larger bearings in smaller housings, multiple flingers, or smaller oiler reservoirs, improper placement may pose challenges. However, even in these extreme cases, effective operation can be maintained by mounting the oiler from the bottom of the bearing housing.

Special Cases: Flinger Flow Issues

In scenarios where flingers are installed, mounting on the opposite side can still be viable. The flinger-induced current, which typically acts as a pumping action, can be mitigated through strategic placement (bottom installation) and operational adjustments.

Recommendations and Conclusions

The traditional guidance advocating for alignment of the Opto-Matic Oiler with the direction of shaft rotation serves as a best-practice recommendation but is not an unyielding rule. Effective operation is still attainable when the oiler is mounted on the opposite side, given that one remains vigilant about specific operational conditions and considerations.

This broader understanding provides greater flexibility for industrial operators and maintenance personnel, particularly in complex or constrained environments. For more specific advice tailored to unique operational conditions, we recommend consulting with our technical support teams, who are committed to ensuring optimal system performance.

Trico Corporation would like to thank Amit Bhatt, Hike Yefremian, and Lev Kirkilevich at Flowserve® Canada Corporation for their contributions to this article.

- Category:

- Lubrication Program

- Application