.jpg)

Dan Freeland

02.08.2022

Maintenance and IT Working Together to Implement IIoT

Corporate Initiatives for the Industrial Internet of Things (IIoT) are the rage these days, and why not? IIoT strategies utilize devices to provide wireless data communication for qualified personnel to interpret and act on accordingly. Some of the real benefits of working smarter with IIoT include:

strategies utilize devices to provide wireless data communication for qualified personnel to interpret and act on accordingly. Some of the real benefits of working smarter with IIoT include: - Improve quality

- Increase process efficiency

- Enabling predictive maintenance strategies

- Improve employee safety

- Make informed decisions

- Reduce equipment downtime costs

- Increase productivity

Sensei Enabled Opto-Matic Oiler Specifications: Sensei Enabled Opto-Matic Oiler – Rated for Hazardous Locations

Trico’s Sensei Enabled Opto-Matic Oiler is one device that enters the IIoT world with some of the same expectations, providing companies the ability to expand their technological endeavors further into the maintenance arena. Ask almost any maintenance or reliability manager, and they will tell you they are spread too thin to accomplish all that is required of them. And what task falls to the bottom of the hot list? Lube routes and checking of the lube levels in equipment. This is because walking lube routes are time-consuming and in general, the equipment is doing just fine. Sensei Enabled Opto-Matic Oiler provides a means, via wireless network, for managing personnel to check oil levels, consumption, and trend data quickly from their computer. This allows for actions to be taken only for equipment in critical or marginal states, reducing lube routes to minutes instead of hours.

This is because walking lube routes are time-consuming and in general, the equipment is doing just fine. Sensei Enabled Opto-Matic Oiler provides a means, via wireless network, for managing personnel to check oil levels, consumption, and trend data quickly from their computer. This allows for actions to be taken only for equipment in critical or marginal states, reducing lube routes to minutes instead of hours.

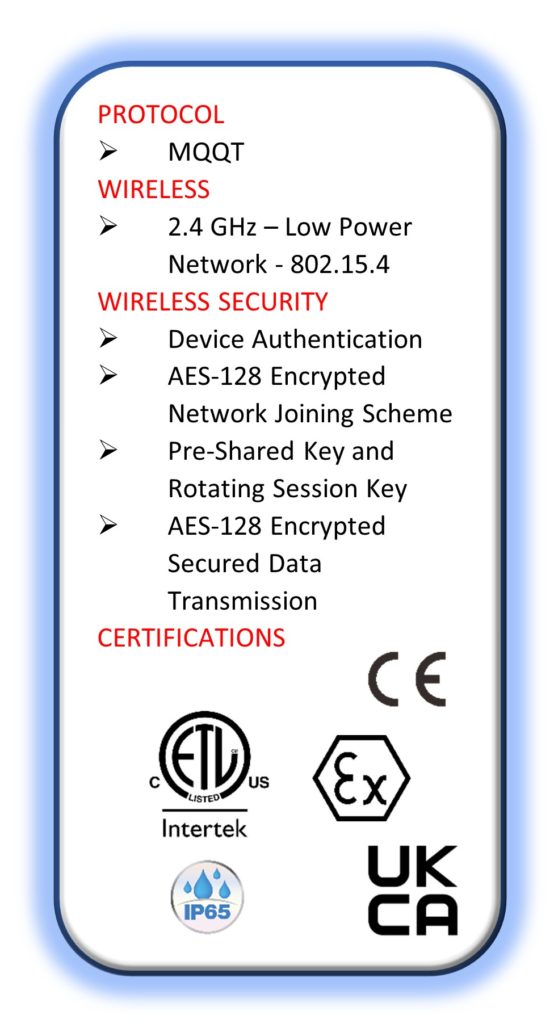

What does IT say?

This sounds like a winner for Maintenance and Reliability, but what will IT have to say about it? Well, Sensei Enabled Opto-Matic Oiler incorporates several key features that IT personnel are looking for end-to-end encryption, for instance, meaning that the data transferred can never be decrypted on the server, in transit, or on the end user’s device. Complete security. Sensei Enabled Opto-Matic Oiler sends independent data via wireless cellular technology to its own infrastructure, so it is “off network” from current inhouse protocols. In addition, Sensei provides flexibility with API integration to allow information being collected to be incorporated into other applications. Working together, IT, Maintenance, and Sensei Enabled Opto-Matic Oiler provides real-time data insights for managers to make time saving decisions while checking many of the boxes that are expected from IIoT devices.

See how Sensei Enabled Opto-Matic Oiler can help you!