Drum Pump Filtration System

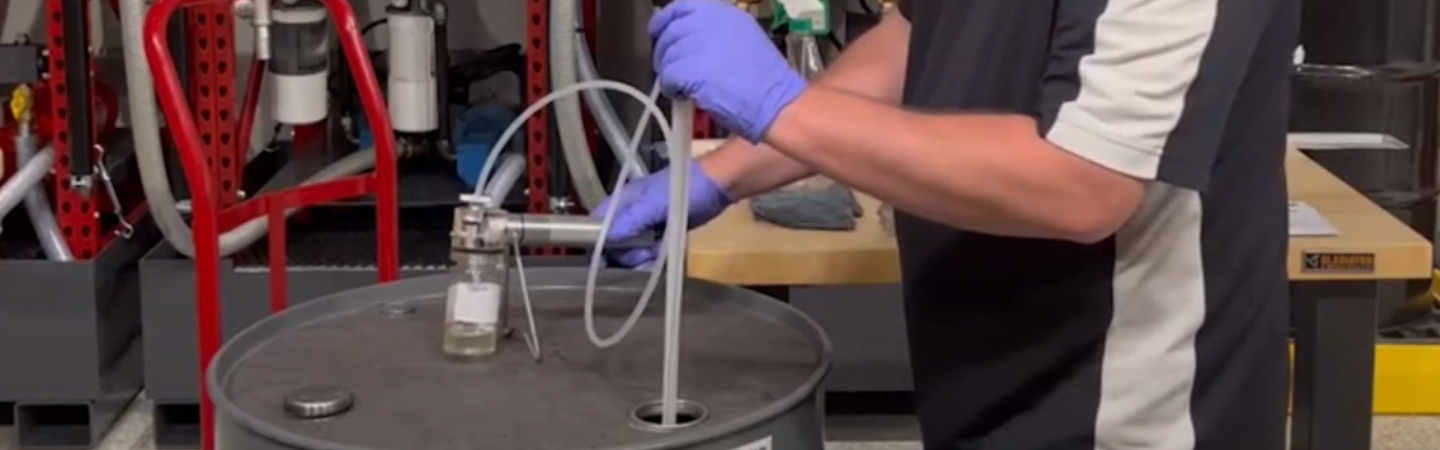

Actively filtering lubricants from storage drums can prevent contamination related problems. Trico’s Drum Pump Filtration System can prevent contamination or remove it when used in daily operations, including filtering oil directly from the storage drum to fill totes and transfer containers.

Feature

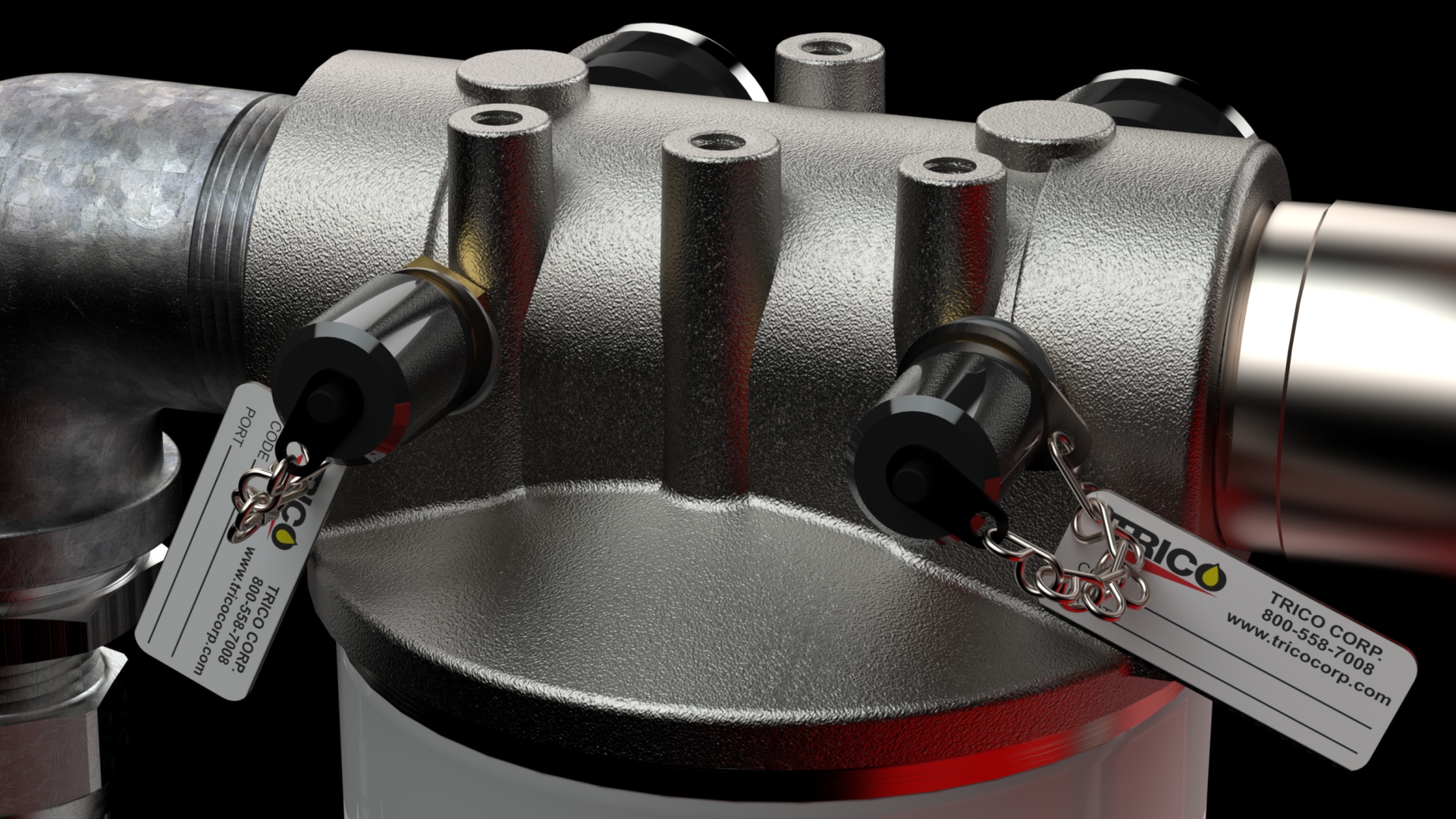

High-Efficiency Filter

The Drum Pump Filtration System comes standard with a 10-micron absolute Beta>200 spin-on filter.

Feature

Sampling Ports

Two sampling ports available for oil sampling before and after the filter media

Feature

Filter Condition Gauges

Differential filter gauges to indicate filter element condition and replacement

Additional Features

- Flow Up to 7.25 gpm

- This system is capable of delivering a flow up to 7.25 gpm and is rated for use with lubricants up to a viscosity of 1250 cSt, depending on motor selection.

- Two Sizes Available

- Pump assembly available for 55-gallon drums and IBC totes

- Flexible

- Dual swivel-ended hydraulic hose for greater mobility and flexibility

- One Motor for Many Pumps

- Hand-wheel modular design for easy transfer of motor to other Drum Pump Filtration Systems

- Motor Options

- Electric and pneumatic motor for Drum Pump Filtration System sold separately

- Versatile

- Use with Drum Pump Recirculation Kit to filter oil in 55-gallons drums

- Integrated Nozzle

- A dispensing nozzle offers a controlled solution for continuous flow and metering of lubricants, and protective rubber nozzle cap to prevent contaminates from entering the nozzle when not in use.

Other Specs

| Model | Description | Tube Length |

|---|---|---|

| 20012 | Drum Pump Only for IBC Totes (without filter) | 47" |

| 30035 | Drum Pump Filtration System for 55 Gallon Drum | 39" |

-

TypeSeal-less/Centrifugal

-

MaterialStainless Steel 316

-

Tube Length39″ (55 gallon drum) and 47″ (IBC tote with filter)

-

Maximum Temperature180°F/82°C

-

Discharge Nozzle1"

-

Discharge Line1″ Hydraulic Hose

-

Hose Line Length6'

-

Filter Media10 Micron Absolute Beta>200

-

Replace Filter Media at20 PSI Differential

.jpg?width=1440&height=450&ext=.jpg)

.jpg?width=1444&height=454&ext=.jpg)