Monitor your equipment - Sensei style.

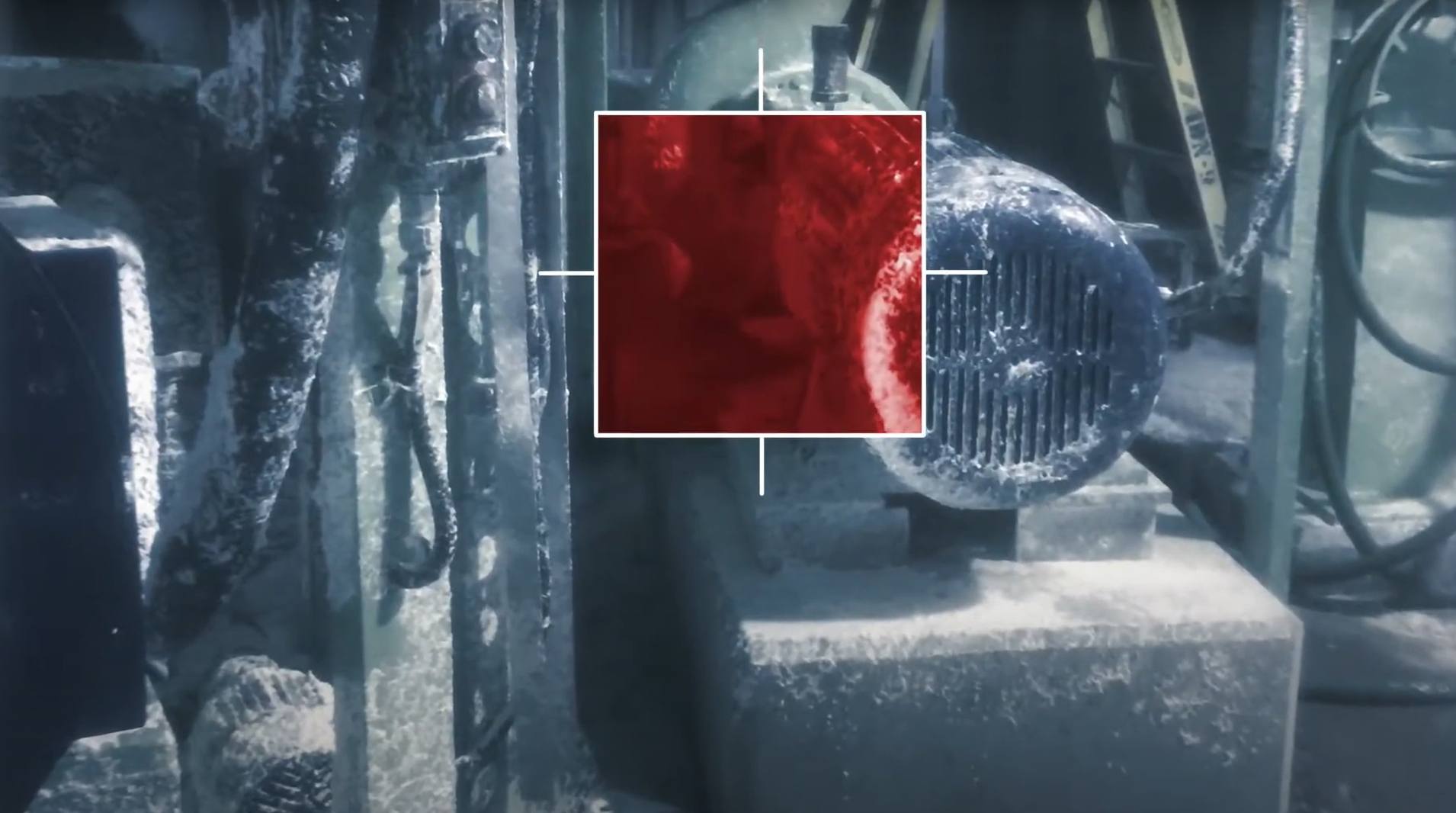

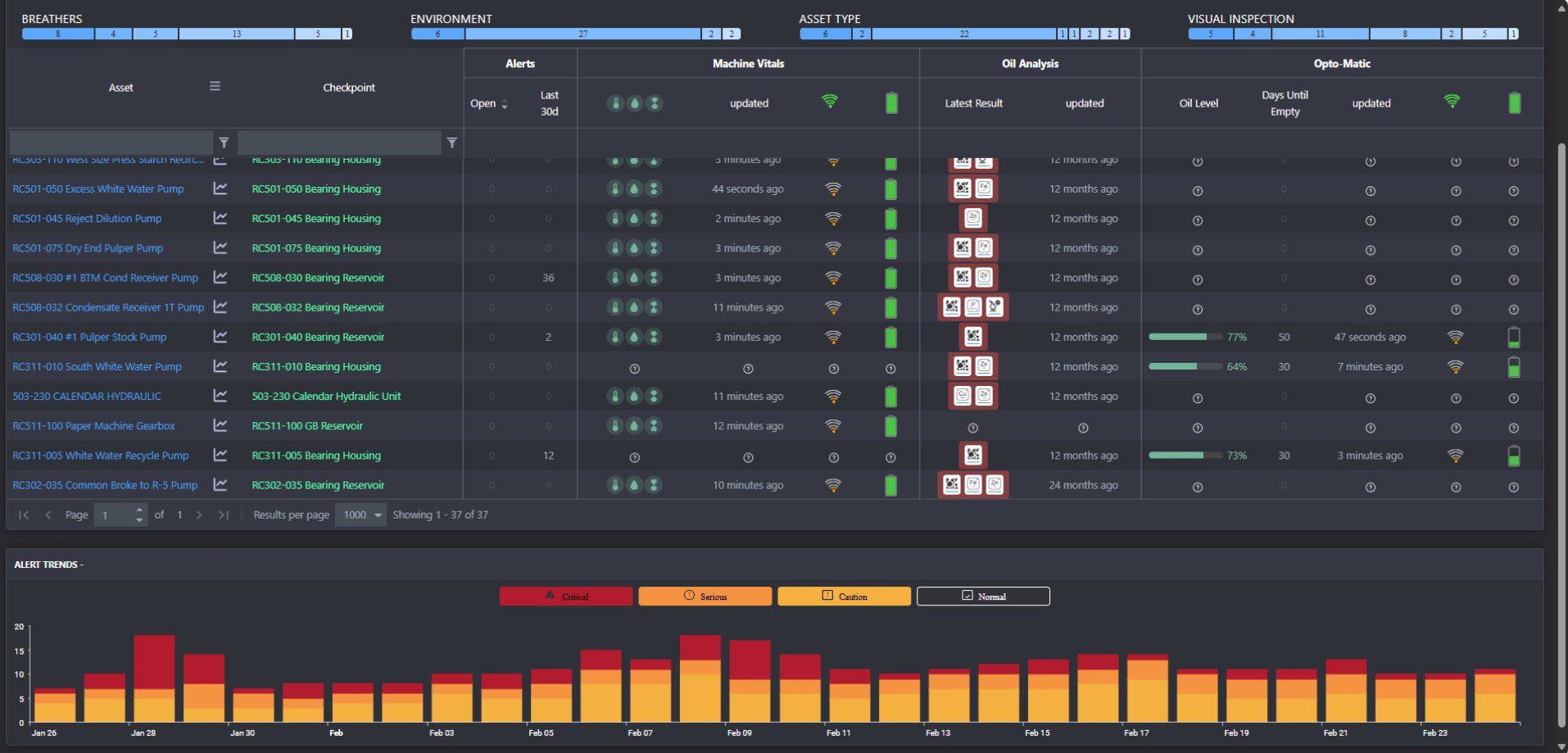

Sensei IIoT Network keeps you continuously informed about lubricant and equipment health - so you can stay ahead of potential problems, while avoiding unnecessary maintenance. It's an ideal opportunity for your plant to make more proactive, data-driven reliability decisions.

01 Improve Reliability

02 Increase Efficiency

03 Powerful Analytics

04 Simple Integration

The Sensei Difference.

No more wondering. No more worrying. No more wasting time.

Powerful

Simple

Secure

Flexible

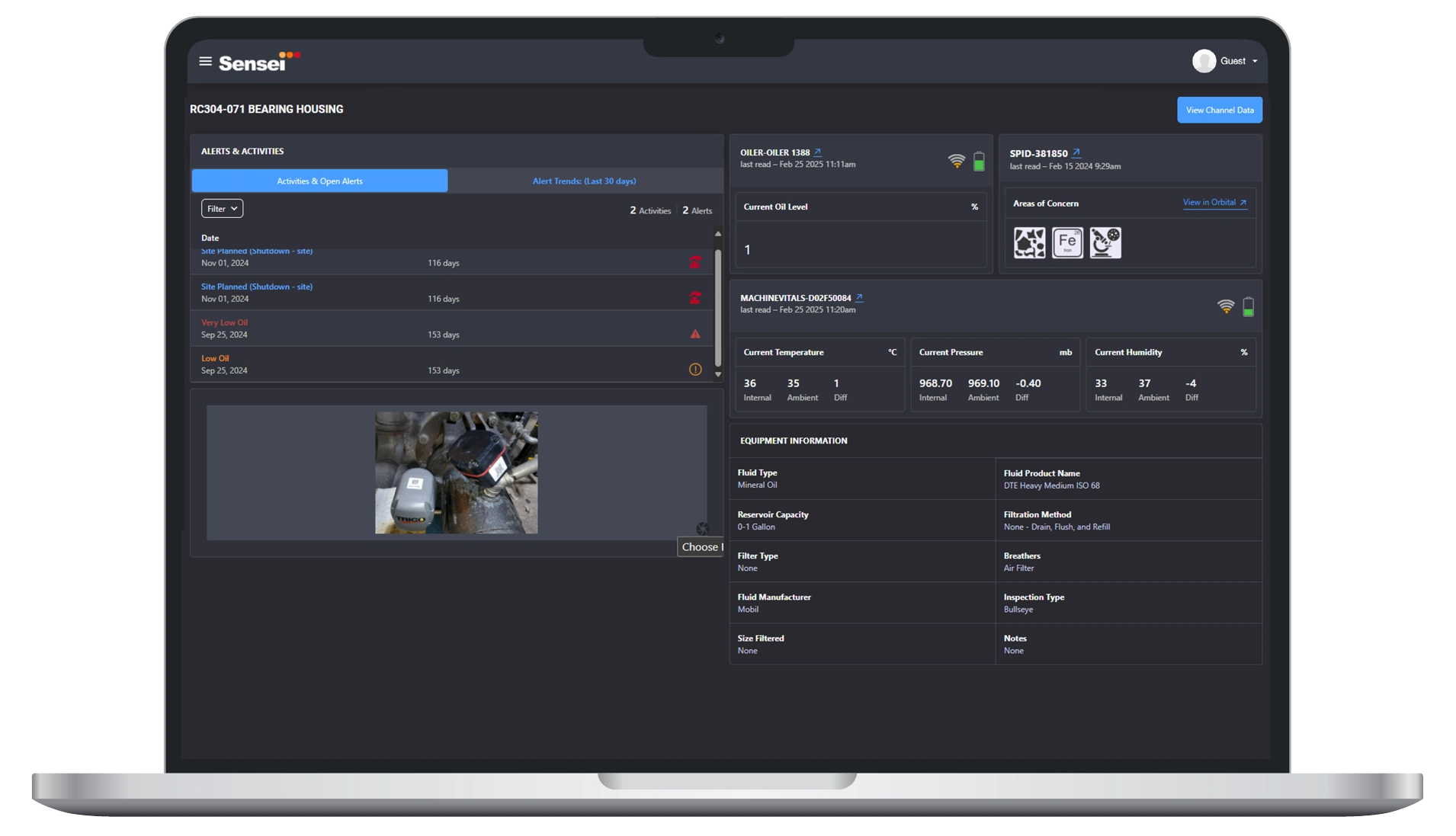

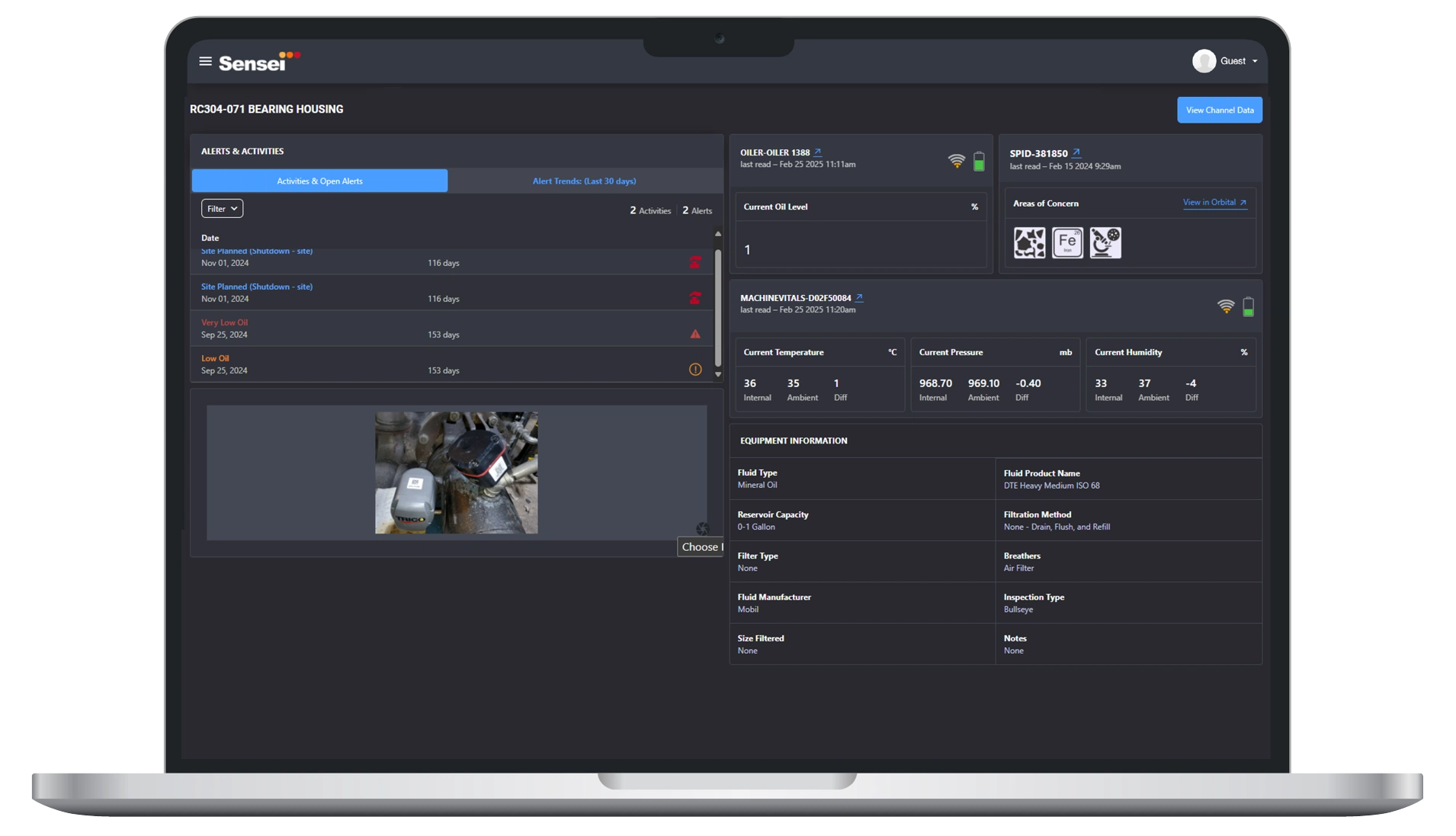

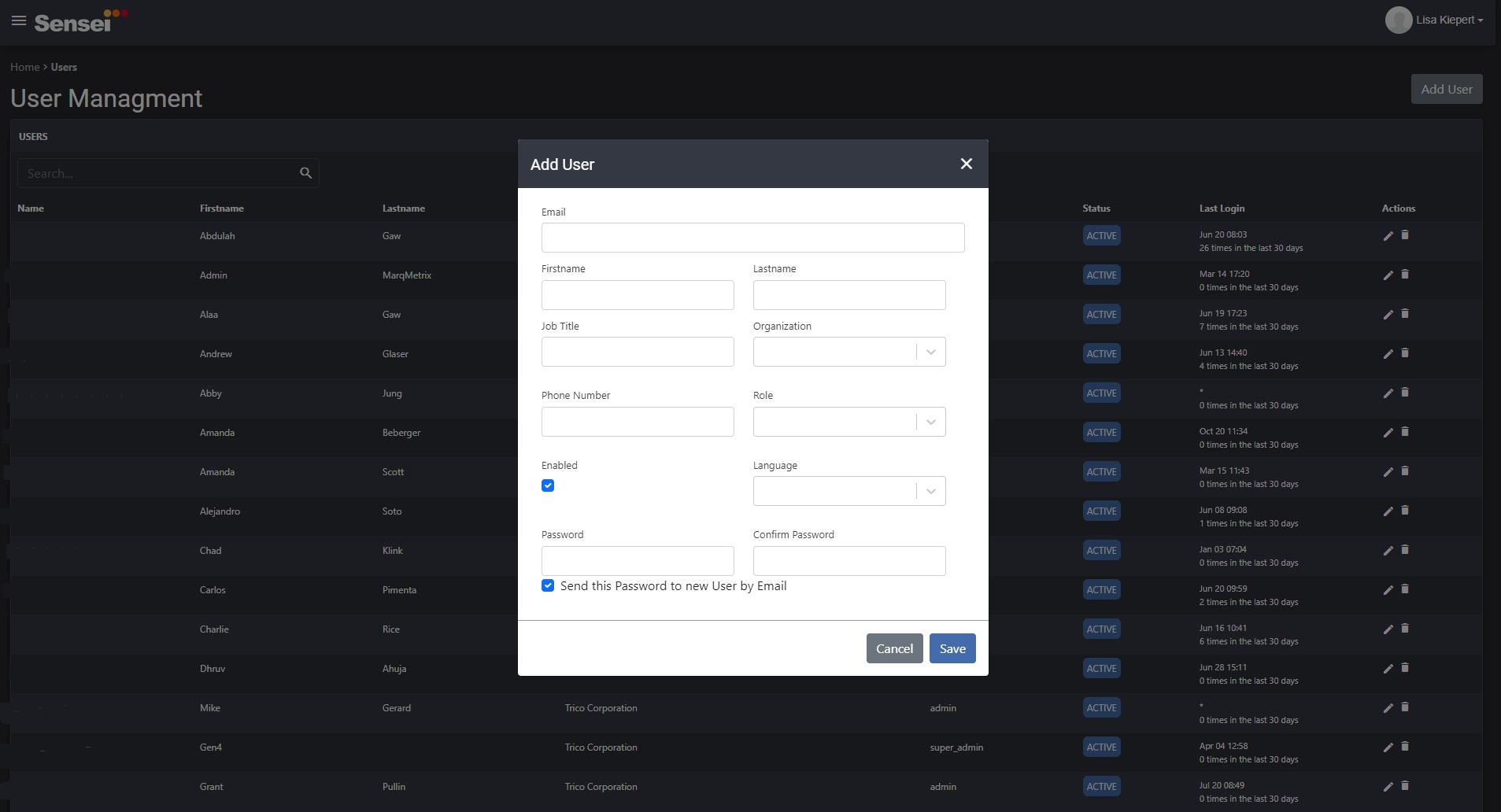

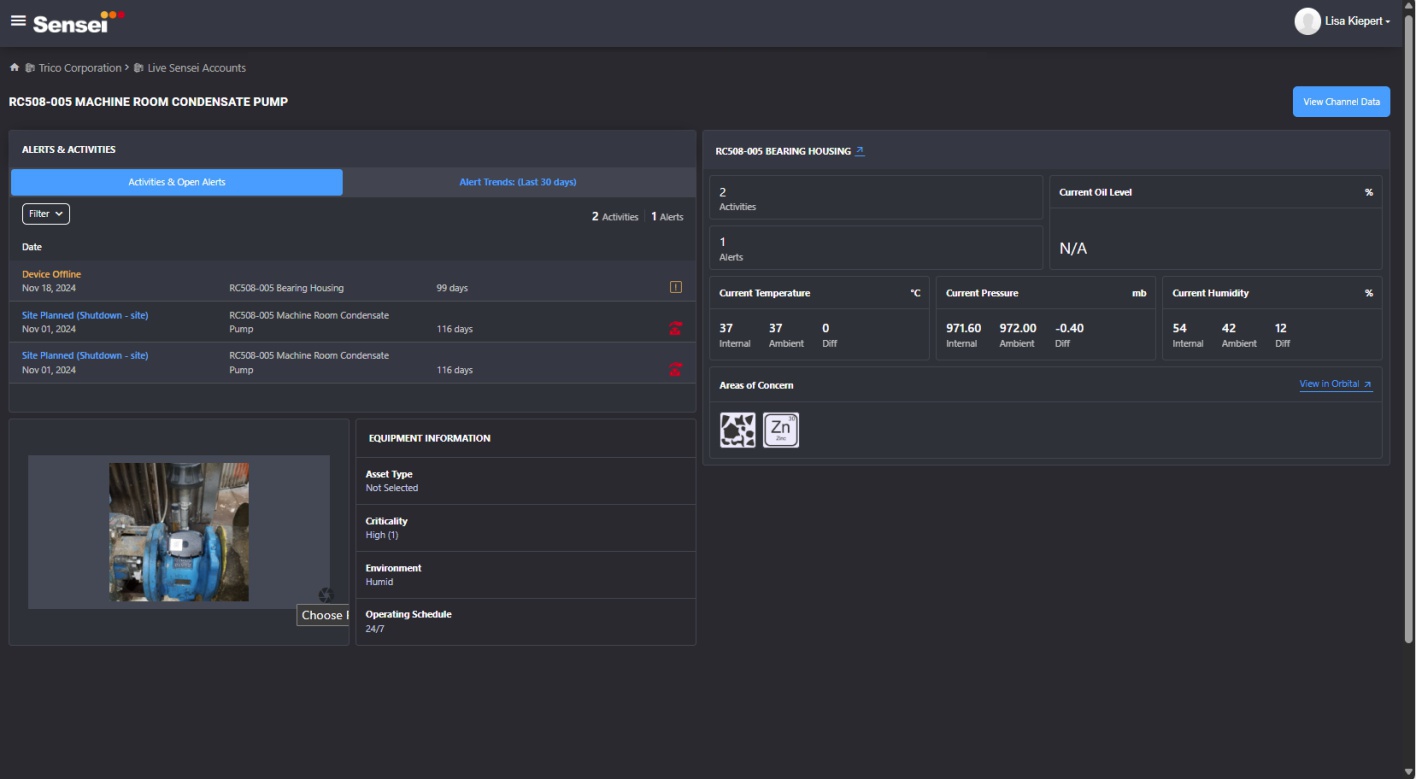

Sensei Platform. The Intelligence.

Your intuitive, web-based dashboard for monitoring and analyzing equipment and lubricant health from Sensei Devices on the network.

What is Sensei?

The Sensei IIoT Network uses wireless sensing devices to provide insights on equipment and lubricant conditions, enabling proactive maintenance. It consists of three components: Sensei Devices, Network Hardware, and the Sensei Platform, forming a Personal Area Network (PAN) for communication across your facility. An optional mobile app assists in adding devices to the network and assigning equipment attributes and recording maintenance activities.