Submitting Oil Samples

Follow these tips for quick, reliable oil sample turnaround.

DO

- Use an appropriate bottle for oil sampling that is clean and dry.

- Make sure the sample bottle is full (minimum of 4 ounces)

- Make sure the cap on the bottle is tightly secured.

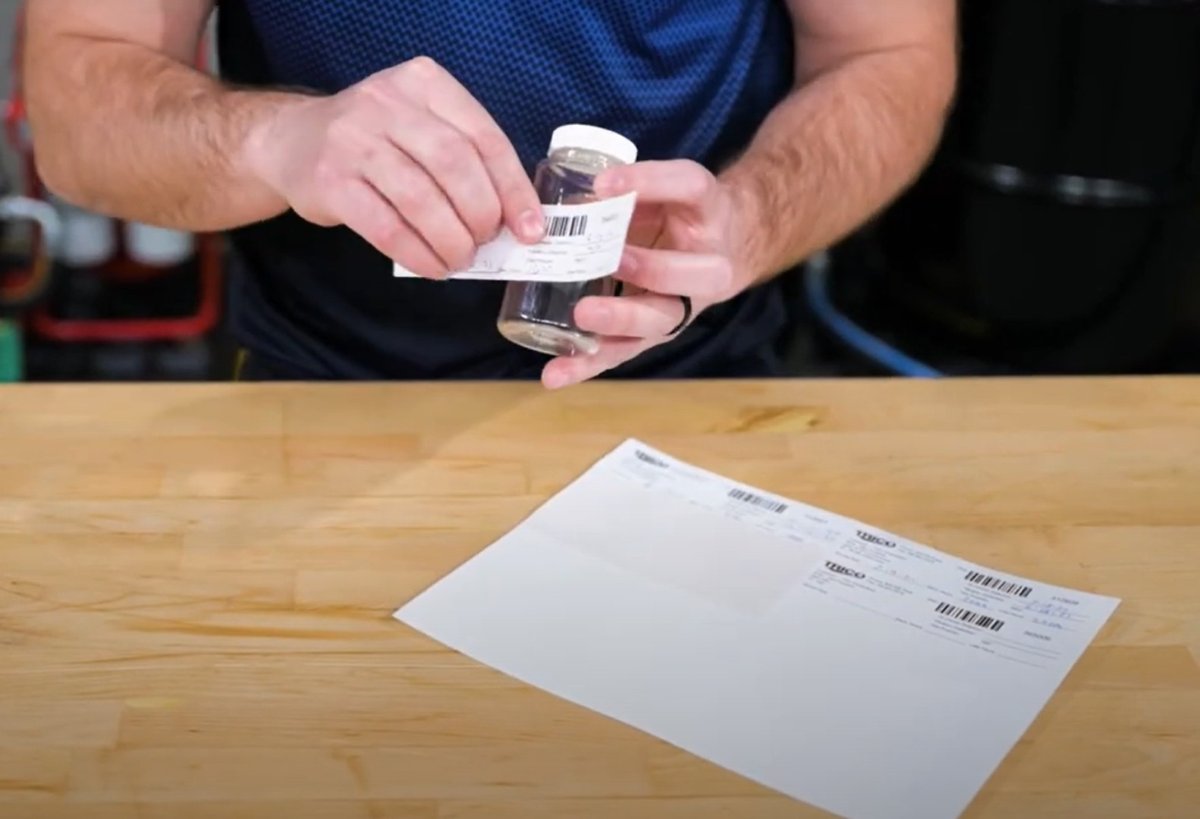

- Write clearly and complete all necessary information on label.

- If mobile app is being used, scan QR code on the bottle, then follow instructions within mobile app.

- Affix label to sample bottle over QR code, if mobile not is being used.

- Verify information for existing sample points is current.

- Notify lab of ANY lubricant changes.

- Ship bottles upright to avoid spillage.

- Ensure purchase order is in place prior to sending samples.

- Inform lab, in advance, if an oil sample requires rush analysis.

- Send sample to lab immediately after it has been drawn.

- Submit a virgin oil sample for each lubricant every year.

- Make sure contact information is up-to-date.

DON’T

- Send oil sample bottles without a label or incomplete information.

- Cross off label information for new equipment.

- Use Scotch tape or masking tape around the cap.

- Return empty oil sample bottles – keep them for your next set of oil samples.

- Reuse ANY sample bottle.

- Use bottles not made for sampling.

- Ship oil sample bottles less than ½ full.

Oil Sample Checklist

7 Things to Do Before Sending Oil Samples

Before sending out your oil samples, make sure you’re setting yourself up for accurate, useful results.

We’ve put together a quick, handy PDF guide you can keep nearby when submitting oil samples.

It covers the key steps to take before you collect and send in your sample. Download the PDF and keep your oil sampling process running smoothly.

Oil Analysis Best Practices

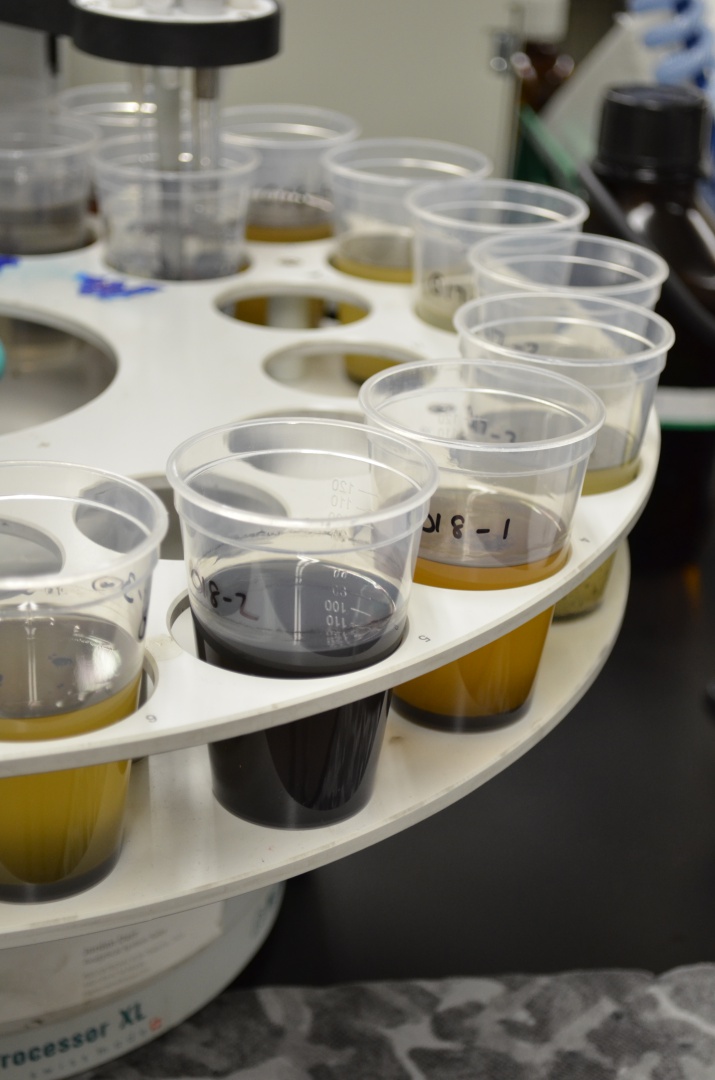

Why Reference Samples Matter

Reference samples are your baseline—the "clean slate" that labs use to compare your in-service oil samples. Without them, it’s harder to detect subtle changes or catch early signs of trouble.

Submitting a current reference sample helps ensure:

- Accurate interpretation of results

- Faster identification of abnormal wear or contamination

- Better trend analysis over time

Be sure to submit an updated reference sample

- At least once a year

- Anytime your brand, viscosity grade, or additive package changes.

Keeping your reference samples up to date ensures your oil analysis stays reliable and meaningful. Download our PDF for more information on why reference samples are important.

Oil Sampling Best Practices

Standard Procedures Matter

Proper oil sampling isn't just about collecting a sample, it's about collecting the right sample, the right way, every time.

That's why following a consistent procedure is so important. From choosing the correct sampling point to minimizing contamination, each step plays a role in the accuracy of your results.

We've put together a downloadable brochure with stand operating procedures (SOPs) for drawing oil samples. Download it and keep it on hand in your lube room, maintenance office, or wherever samples are drawn.

Consistency starts with a clear procedure and we've got you covered.

Making Sense of Your Oil Analys Reports

How to Read an Oil Analysis Report

An oil analysis report can tell you a lot, if you know what to look for. From wear metals and viscosity to contamination levels and flagging limits, it's easy to get overwhelmed by numbers and abbreviations.

That's where we come in. We've created a downloadable guide that walks you through the key sections of a standard oil analysis report.

Download the guide and start reading your reports with confidence. Understanding your report turns data into decisions and better equipment reliability.

Help

Need Help with Oil Analysis

Contact One of Our Experts

Not sure if you’re collecting samples correctly? Wondering how often to test? Trying to make sense of trends or flagging limits?

You’re not alone—and we’re here to help.

Whether you're setting up a new oil analysis program or fine-tuning an existing one, we can provide guidance on:

- Sampling intervals and locations

- Interpreting test results

- Setting up reference samples

- Choosing the right testing parameters for your equipment

Have a question? Need a second opinion?

Reach out to us anytime. We're happy to talk through your program and help you get the most out of your oil analysis efforts.

Contact us by calling (262) 691-9336, ext 722 or emailing oilanalysiscs@tricocorp.com. Let’s keep your equipment running smoothly and your data working harder for you.

Not sure if you’re collecting samples correctly? Wondering how often to test? Trying to make sense of trends or flagging limits?

You’re not alone—and we’re here to help.

Whether you're setting up a new oil analysis program or fine-tuning an existing one, we can provide guidance on:

- Sampling intervals and locations

- Interpreting test results

- Setting up reference samples

- Choosing the right testing parameters for your equipment

Have a question? Need a second opinion?

Reach out to us anytime. We're happy to talk through your program and help you get the most out of your oil analysis efforts.

Contact us by calling (262) 691-9336, ext 722 or emailing oilanalysiscs@tricocorp.com. Let’s keep your equipment running smoothly and your data working harder for you.

.jpg?width=350)