Get Ahead of the Curve

Upgrade Your Maintenance and Reliability Processes

Machine VitalsTM is perfect for maintenance and reliability personnel who take a proactive approach to predictive maintenance. Its innovative technology monitors and analyzes equipment condition to improve reliability.

Track your equipment's condition in real time to address problems more quickly. Identify trends and predict issues with data visibility to reduce downtime, prevent failures, and save money.

Unleash the Power of Data

Machine Vitals empowers you to collect, analyze, and act on critical data, enabling you to optimize equipment performance and prevent costly failures. With Machine Vitals, you can eliminate unnecessary manual inspections, gain a comprehensive understanding of equipment behavior under different conditions, remotely monitor assets from anywhere, and make better decisions with complete visibility. Uncover root causes of issues and track data-dense performance trends effortlessly.

01 Collect Data

.jpg)

02 Analyze Data

03 Act on Data

The Power of Machine Vitals

A Multi-Parameter Approach for Early Detection and Proactive Maintenance

By measuring multiple parameters, Machine Vitals provides a comprehensive understanding of your equipment's condition. This provides:

- Holistic Understanding: By measuring multiple parameters, Machine Vitals provides a comprehensive view of your equipment's condition. These parameters are interrelated and monitoring them collectively allows for a holistic understanding of equipment performance.

- Early Detection of Issues: By analyzing variations in temperature, humidity, pressure, acoustics, and acceleration, Machine Vitals can detect early signs of abnormalities, allowing you to take preventive action. Early detection enables you to address issues before they cause significant downtime, costly repairs, or safety hazards.

- Discovering Hidden Problems: Some issues may not be apparent through conventional analyses or routine inspections. The combination of various parameters measured by Machine Vitals can uncover hidden problems that may not be known through traditional monitoring or oil analysis alone.

Understanding the importance of these parameters and their interplay allows you to take a proactive approach to maintenance, optimize performance, and ensure the long-term reliability of your equipment.

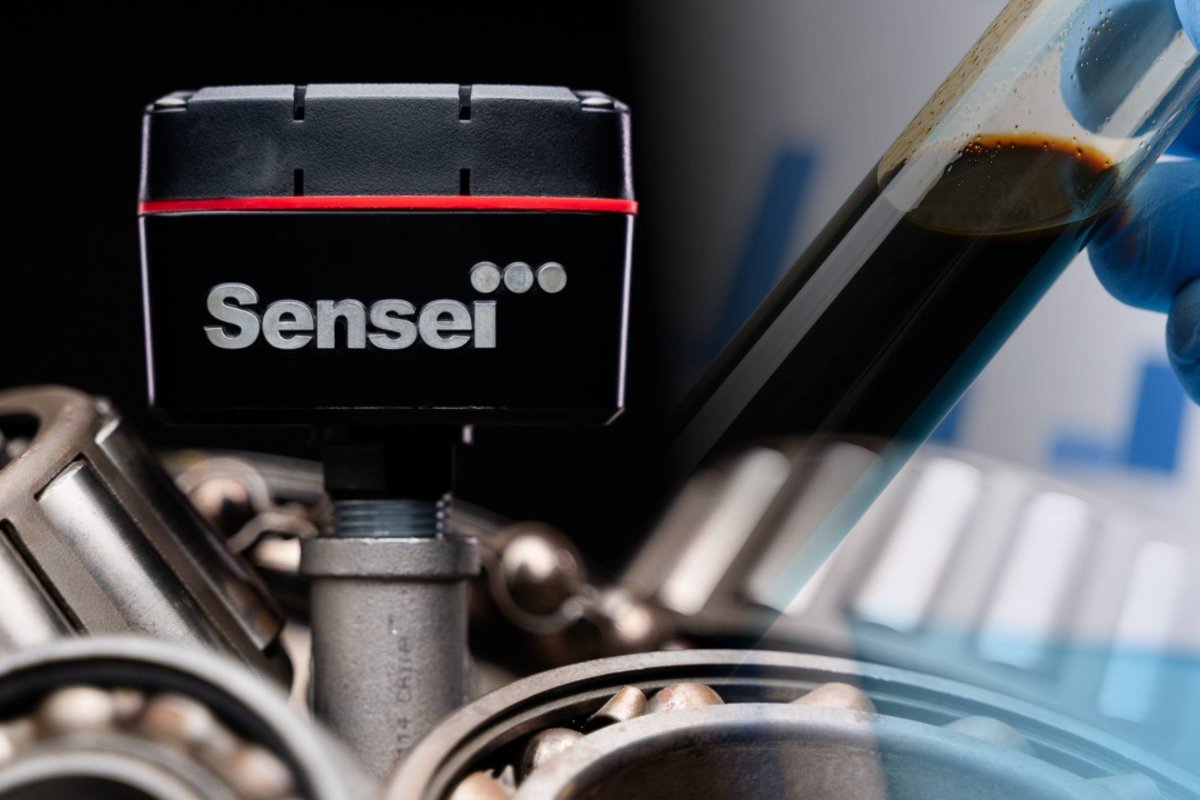

Machine Vitals and Oil Analysis

A Comprehensive Approach to Equipment Health

Oil analysis has long been a valuable diagnostic tool for assessing lubricant and equipment health. Machine Vitals is an invaluable complement to oil analysis, filling in the gaps and providing additional insights into the condition of your equipment. With the combination of both oil analysis and Machine Vitals you’ll have a complete understanding of your lubricant and equipment’s condition.

The System

.jpg)

Seamless Communications

Robust Hardware Ensures Reliable Data Collection

Machine Vitals hardware components, including the Gateway and Repeater, ensure seamless integration and reliable data transmission across your facility. The Gateway is the central hub, collecting and transmitting data from multiple Machine Vitals, while the optional repeater extends the range for and strengthens the signal. With this robust hardware foundation, Machine Vitals delivers accurate and continuous insights for efficient condition monitoring.

Simplify Data Monitoring and Analysis

Machine Vitals is complemented by the intuitive Sensei® Platform. This platform provides an all-in-one solution for monitoring, analyzing, and managing your equipment data. With the Sensei Platform, you can easily view trends, access historical information, and make informed decisions to optimize your operations.

Additional Features

- Elimination of Equipment Inspections

Bid farewell to time-consuming manual inspections as Machine Vitals enables continuous monitoring, eliminating the need for frequent physical checks of equipment.

- Postmortem Failure Analysis Data

Gain valuable insights from post-failure data analysis, enabling you to understand the root causes of breakdowns and prevent future occurrences.

- Aggregated Site Performance

- Obtain a holistic view of your entire facility's performance, allowing you to identify trends, patterns, and areas for improvement.

- Custom Alerts and Alarms

- Stay informed about critical machine conditions with customizable alerts and alarms, ensuring timely interventions and preventing costly downtime of operations.

- Multi-Application Design

Machine Vitals versatility allows it to be used across various equipment types and lubrication points, providing flexibility and cost-effectiveness.

- Comparative Analysis

Identify performance variables by comparing equipment types, locations (inside/outside), and oil types. This data-driven approach enables targeted maintenance strategies.

Other Specs

| Model | Description | Fitting Connection |

|---|---|---|

| 38310 | Machine Vitals Device | 1/2" NPT |

-

Dimensions

H 3.34” x W 2.63” x L 3.25”

-

Thread Connection

½” NPT

-

Power

3.6 Volt D Size Battery

-

Environmental

Indoor/outdoor use (Designed to IP65)

-

Battery Life

3 years (depending on data and frequency settings)

-

Material

Cover: polycarbonate

Base: powder coated aluminum

-

Temperature

0°-175° F (-18º to 79ºC)

-

On/Pairing Switch

Magnetic – top cover clear area

Frequently Asked Questions

Here are some of the most frequently asked questions regarding Machine Vitals. If you have any further questions or need additional information, don't hesitate to contact us at inquiries@tricocorp.com. We are here to assist you every step of the way.

.jpg?width=1200)