.jpg)

Victoria Bunchek

03.08.2022

Journey of the Lubricant® is a Key Piece of Oil Intelligence

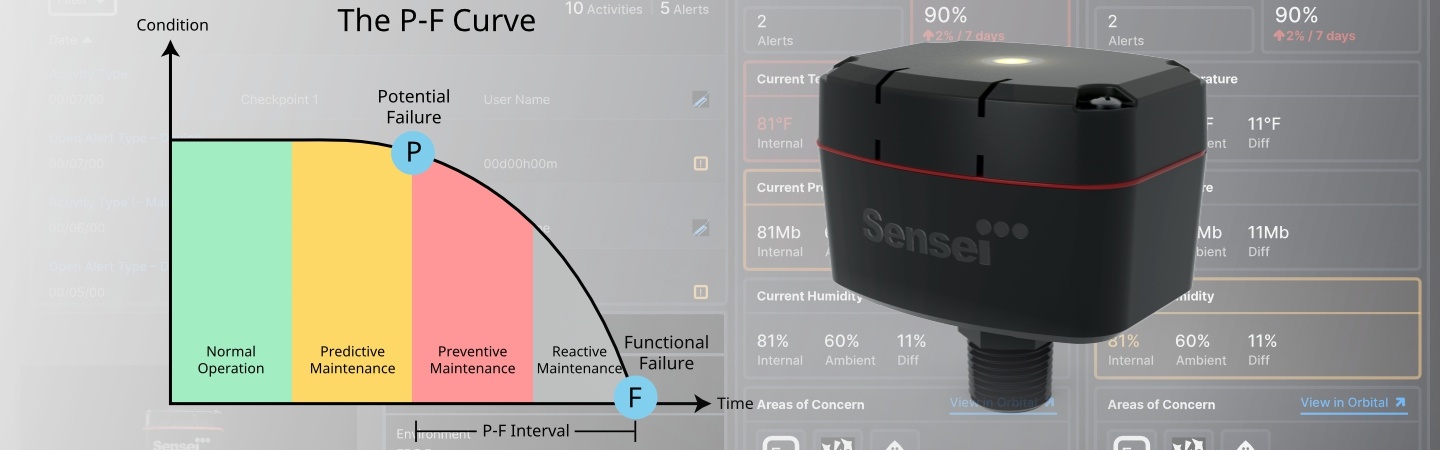

Oil analysis is used as an early detection of problems in equipment; however, issues tend to start well before the lubricant ever reaches the intended application. Trico’s philosophy focuses on the practices that are directly impacting the equipment – from the time the lubricant arrives to the time its life is spent in the equipment. We call this Journey of the Lubricant and believe this the best methodology when evaluating a reliability program and its practices.The Journey of the Lubricant is broken down into 5 stages – Arrival, Storage, Transfer, Application, and Lifecycle. Adding oil analysis at these different stages, which we refer to as dimensional sampling, provides deeper, more valuable insight into the viability of your equipment lubricants and your practices.

Using these multiple data points and continuously cross-referencing and interpreting the relationships among them you can uncover answers that make a real impact on your lubricants, your equipment, and your whole operation. We call this more complete application of knowledge – Oil Intelligence. Utilizing this approach, you can look at each Journey of the Lubricant stage individually and implement incremental changes that can make a significant impact.

- Arrival – Performing oil analysis at this stage is essential from a forensic standpoint. Without a reference sample, diagnosing problems later in the Journey of the Lubricant becomes difficult because there will be more variables to eliminate. It is also important to do oil analysis at this stage as it provides an indication of the condition and care your supplier has taken to ensure lubricant is proper and contaminant free.

- Storage – Storage reference samples begin to identify how your practices are impacting your lubricant condition. This includes environmental ingression, cross-contamination of drum pumps, and improperly sealed or left open bungs that introduce water and particulate contamination into the lubricant.

- Transfer – Transfer reference samples provide the best baseline for equipment test results. Any changes from storage to transfer are affected mostly by personnel interactions. This includes the use of cross-contaminated equipment, and improperly sealed or open transfer containers. These factors can introduce contaminants and can cause the onset of chemical reactions compromising the condition of the lubricant.

- Application – Improper equipment configuration can allow contaminants into your system or cause the production of wear particles from inadequate lubrication. Oil Analysis offers the earliest warnings about things that could go wrong and spot signs of wear.

- Life Cycle – The most effective maintenance programs incorporate on-going, routine oil analysis and data trending for continuous improvements and monitoring of lubricant and equipment condition.

Stop doing oil analysis. Start doing Oil Intelligence.

Oil Intelligence moves you beyond random, routine, or reactive oil analysis, to a more data-driven, proactive approach. Let Trico help you delve deeper into oil analysis data by exploring the possibilities of what can be monitored through the Orbital Platform by viewing this short video.

- Category:

- Oil Analysis

- Tags:

- Predictive

- Storage

- Lifecycle