Dan Freeland

02.06.2024

Desiccant Breathers the Clear Choice

I have heard recently that some companies have decided to move away from desiccant breathers and replacing them with traditional air breathers. In some instances, this may be just fine but, in most of the plants that I’ve been in, the environment is hot and very humid. Making this kind of decision in haste can cause all kinds of expensive problems. Desiccant breathers offer several advantages over traditional air filter vents, making them a more effective choice for protecting industrial equipment from contamination and moisture. Here's why they are considered better in many applications:

Moisture Absorption

The most significant advantage of desiccant breathers over traditional air vents is their ability to absorb moisture from the incoming air. Traditional air filter vents can prevent particulate matter from entering the system but do little to control the moisture content of the air. Desiccant breathers contain silica gel or similar materials that effectively remove moisture, thereby protecting sensitive components from corrosion, rust, and other moisture-related damages.

Improved Filtration Efficiency

Desiccant breathers often feature multi-stage filtration systems that are more effective at removing both particulate contaminants and moisture compared to traditional air filters. These stages can include particulate filters at various micron levels, ensuring that the air entering the system is both clean and dry. This multi-stage approach provides superior protection against a broader range of contaminants.

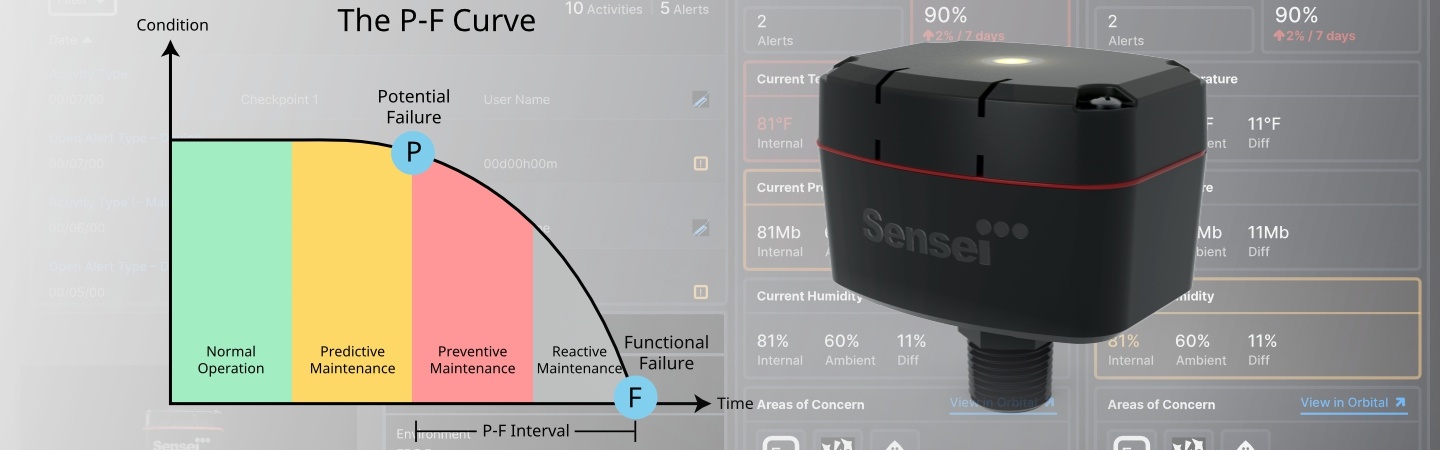

Cost-Effectiveness and Efficiency

By combining moisture absorption with high-efficiency particulate filtration, desiccant breathers enhance the overall efficiency and reliability of equipment. They can reduce the need for frequent maintenance, prolong equipment life, and prevent costly downtime due to moisture or particulate damage. Over time, the initial investment in a desiccant breather can result in significant savings compared to the costs associated with using traditional air filter vents and dealing with the consequences of moisture and particulate contamination.

Adaptability and Customization

Desiccant breathers can be designed to fit a wide range of applications and environmental conditions. They come in various sizes and configurations, with different types of desiccants and filtration capabilities to meet specific requirements. This adaptability makes them suitable for a wide variety of industrial applications, from hydraulic systems and gearboxes to storage tanks and transformers.

Desiccant breathers offer a comprehensive solution for air quality control in industrial systems, addressing both particulate and moisture contamination in a way that traditional air filter vents cannot match. Their ability to absorb moisture, combined with superior filtration capabilities, makes them a preferred choice for protecting and enhancing the performance of industrial equipment.

_______________________________________

**PRODUCT UPDATE 2/1/2024**- Trico is excited to share enhancements across our desiccant breather product line, now featuring both orange/green and blue/pink desiccant options. The EX-series breathers check valves are shielded, ensuring they remain free from clogs and stickiness upon exposure. Additionally, the Particulate Filter is 3-microns crafted from dual-phase micro-glass for superior filtration. The updated Watchdog Desiccant breathers have a versatile “tri-fit” connection, compatible with 1-inch or 3/8-inch male threads, adaptable for NPT, BSPT, or BSPP standards. Discover the new and improved Watchdog Desiccant Breathers today!