SprayMaster II Coolant System

The SprayMaster II Coolant System is designed for applications where the ability to cycle the coolant delivery is required. Solenoid control of spray coolant allows instant on-off operation for use in secondary machining.

Feature

Solenoid Controls

Solenoids control the on/off timing for cyclic applications. They provide instant flow once energized and can be wired to provide an off cycle for loading and unloading parts. They also conserve on coolant use during load and unload portion of cycle.

Feature

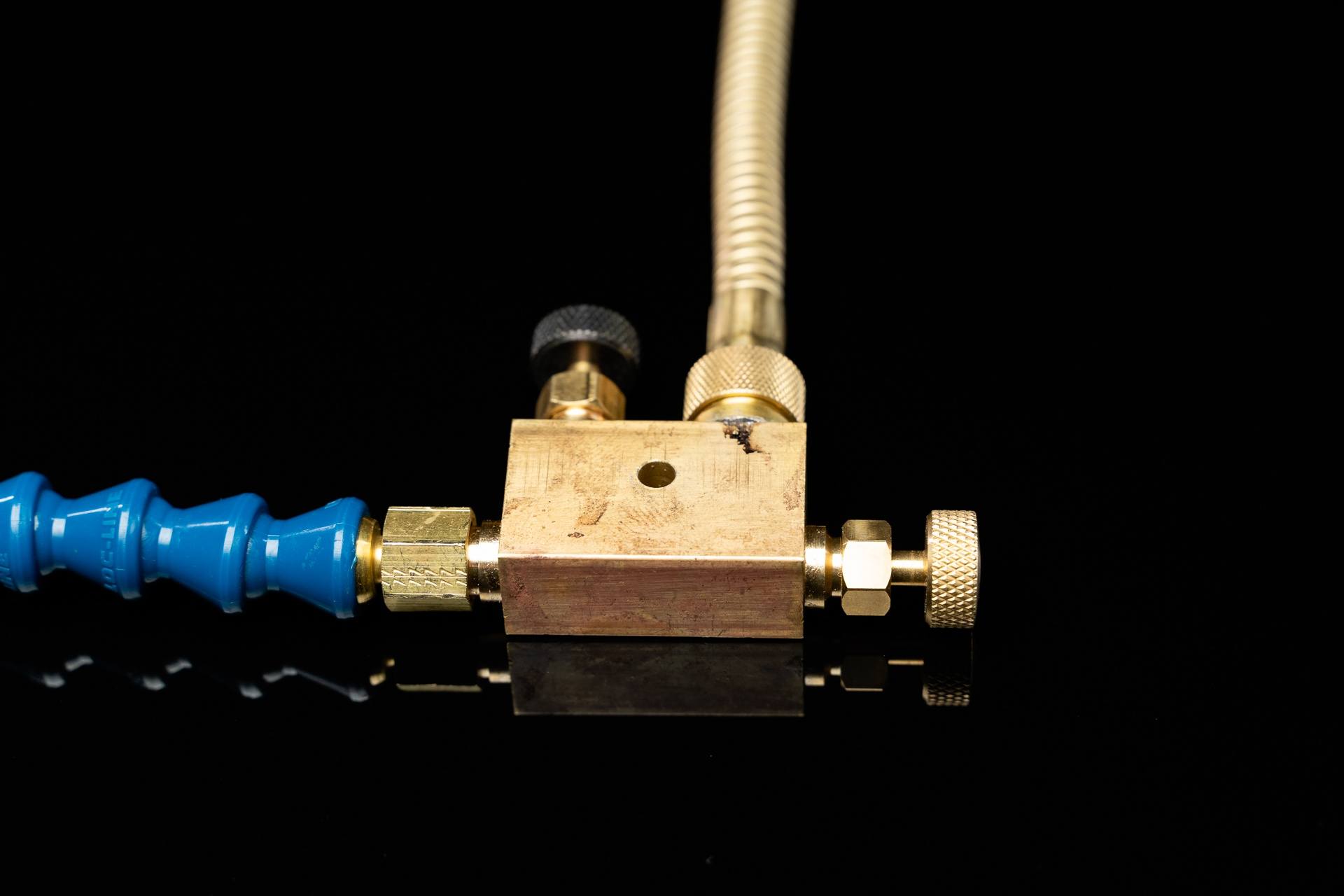

Independent Controls

Controls at the nozzle allow the user to adjust air and liquid flow without having to be immediate proximity to the tank, where most other unit's controls are located. Separate air (black) and liquid (gold) needle valves allows for independent air and liquid flow. Use less coolant with high air flow for increased chip clearing power while reducing overspray. Some air is still required as it is what creates the syphon effect for the liquid flow.

Feature

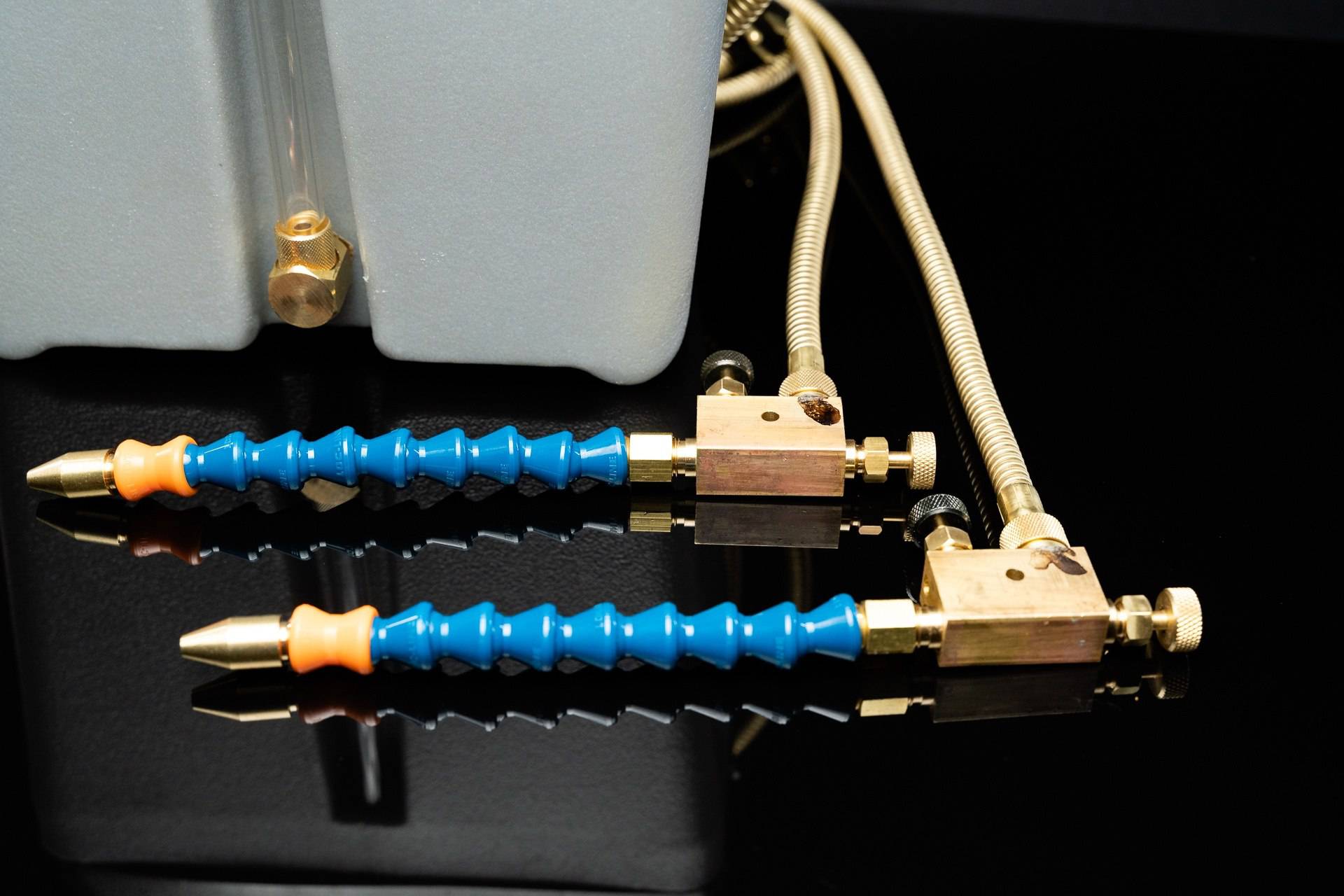

Nozzle Assembly

One or two 7-inch flexible segmented plastic nozzle(s) come standard with five-foot delivery line(s). The armored brass protects the internal plastic delivery lines from melting from hot metal chips.

Additional Features

- Low Profile Mounting Bracket

Mounting bracket affixed to the back of the tank accepts (2) 5/16" diameter screws at a distance of 8 inches (HDPE and SS tank)

- Large Reservoir

One-gallon reservoir capacity at a practical size of 12-1/4"(H) x 10" (W) x 5-1/4" (D)

Other Specs

| Model | Description | No. of Lines | Length of Lines (ft) | Capacity (gal) |

|---|---|---|---|---|

| 30458 | Spraymaster II | 1 | 5 | 1 |

| 30459 | Spraymaster II | 2 | 5 | 1 |

-

ReservoirHigh Density Polyethylene

-

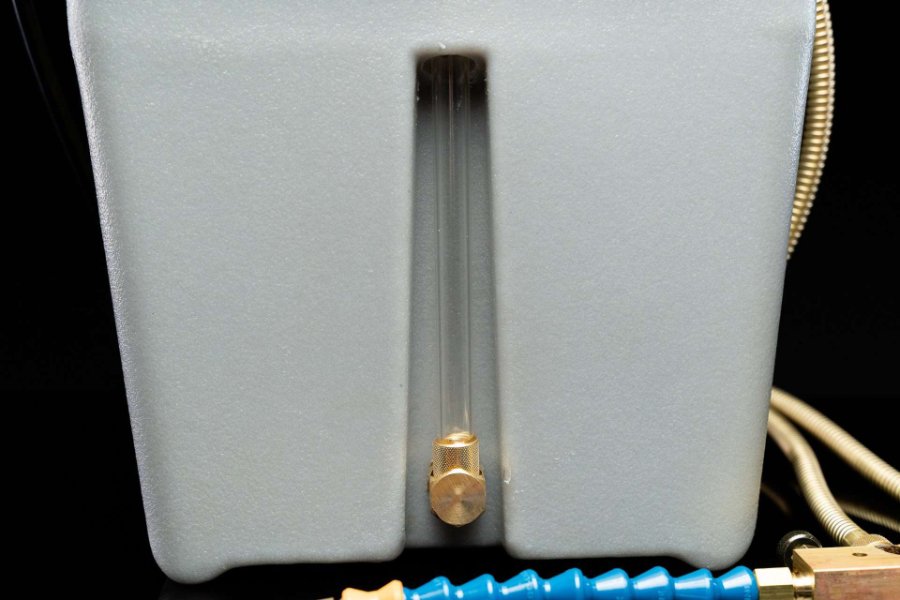

SightAcrylic Plastic

-

ValvesBrass

-

SealsBuna-N

-

Delivery Line5 ft. Brass Armored

-

Coolant TubePolyurethane

-

Filter Elements40 x 40 Mesh Stainless Steel

-

SolenoidBrass Body & S/S Plunger

-

Air Inlet1/4″ NPT

-

Air Inlet Pressure50-100 PSI